Some time ago, I have serviced a Lip Nautic Ski dive watch. Back in the days of its construction, there was yet another model line of even better protected Nautic Skis, which was called - why not - »Super« Nautic Ski. Here is one - although wasted and not running:

The Super Nautic Ski's case (Super-Compressor by EPSA) is significantly bigger than those of other N-Skis allowing for recessed crowns. It's thus impossible to drown the watch by knocking one of them off under water.

The caseback (reversed photo...) features an eagle logo and is scarred by unsuccessful attempts to open the case (there is a dedicated case wrench for this purpose). This does not have to be entirely bad, as it suggests that the movement has not been tampered with too much.

With the case finally open, the LIP R184 movement seems almost NOS-like with what appears to be a 1970s button cell.

Apparently, the cell has leaked (orange circle) and one of the two movement holder screws is broken (blue circle). This rises the question where to find its head and bracket ...

Voilà, the bracket has become a part of the wheel train (a blocking one of course) just as the screw´s head which I also found in there.

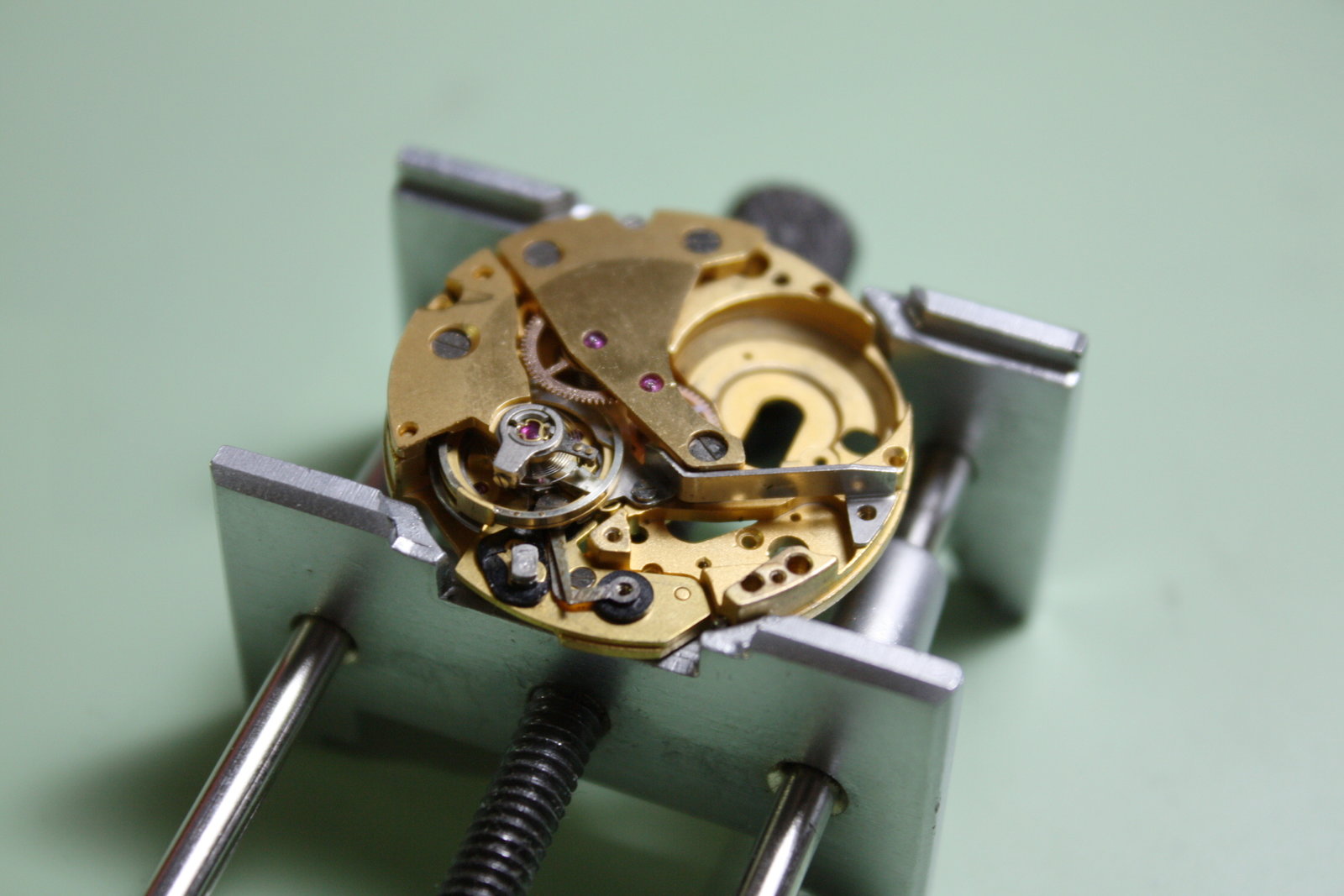

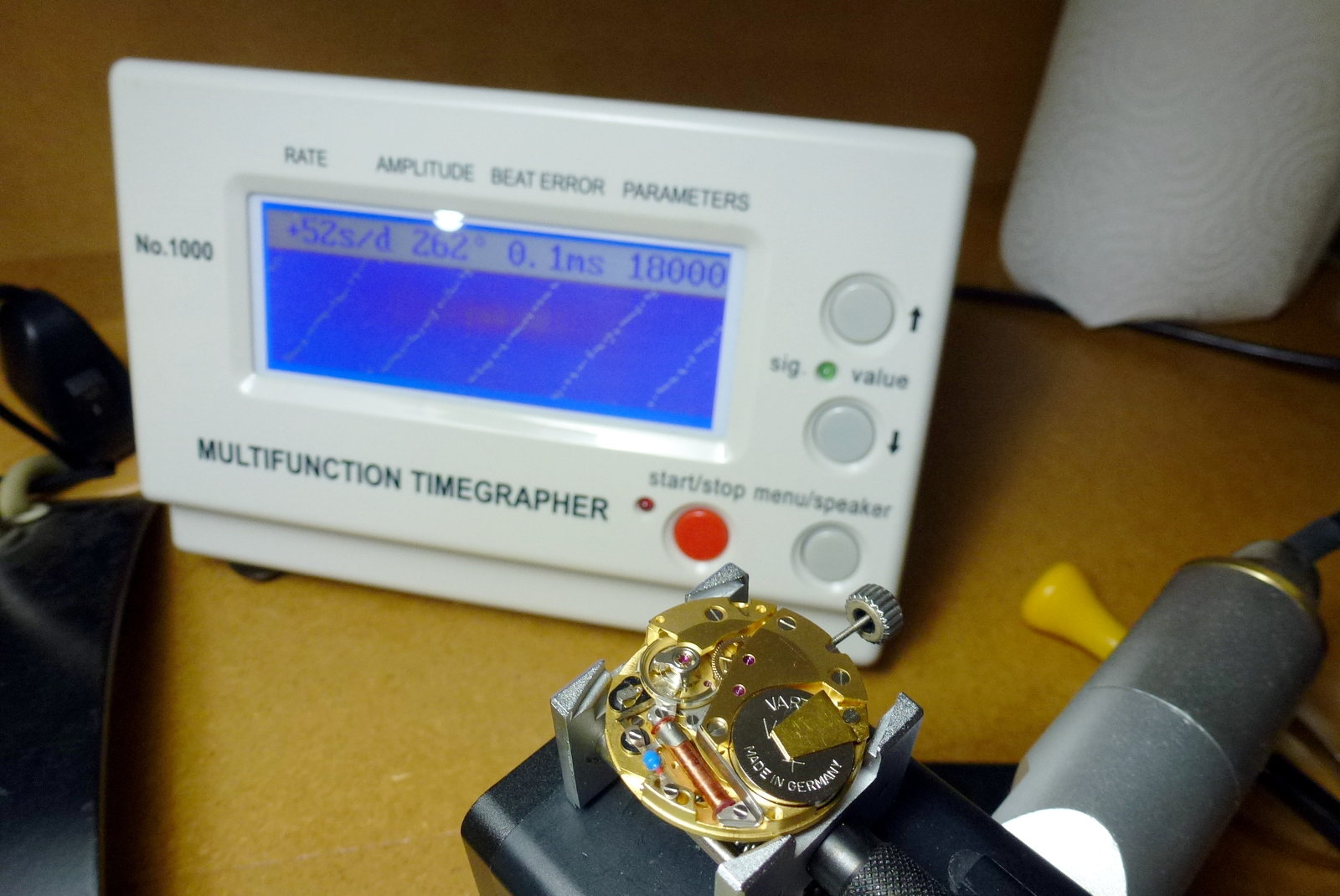

Removed from the case and powered by a new battery...

...the movement shows +3 mins per day on the timegrapher. A service is thus highly indicated.

Movement teardown

With hands and dial off the date disc is fully visible.

There is nothing holding it down except the coppery washer.

The date change mechanism - there is no quicksetting feature which is a significant drawback of the R184 (imo).

Under the latter we find the keyless works on the left...

...and get access to the "L"-shaped battery contact spring with its huge center screw. To avoid a short circuit, this whole part - it goes to the negative pole of the battery - needs to be isolated from the rest of the movement (connected to the positive pole).

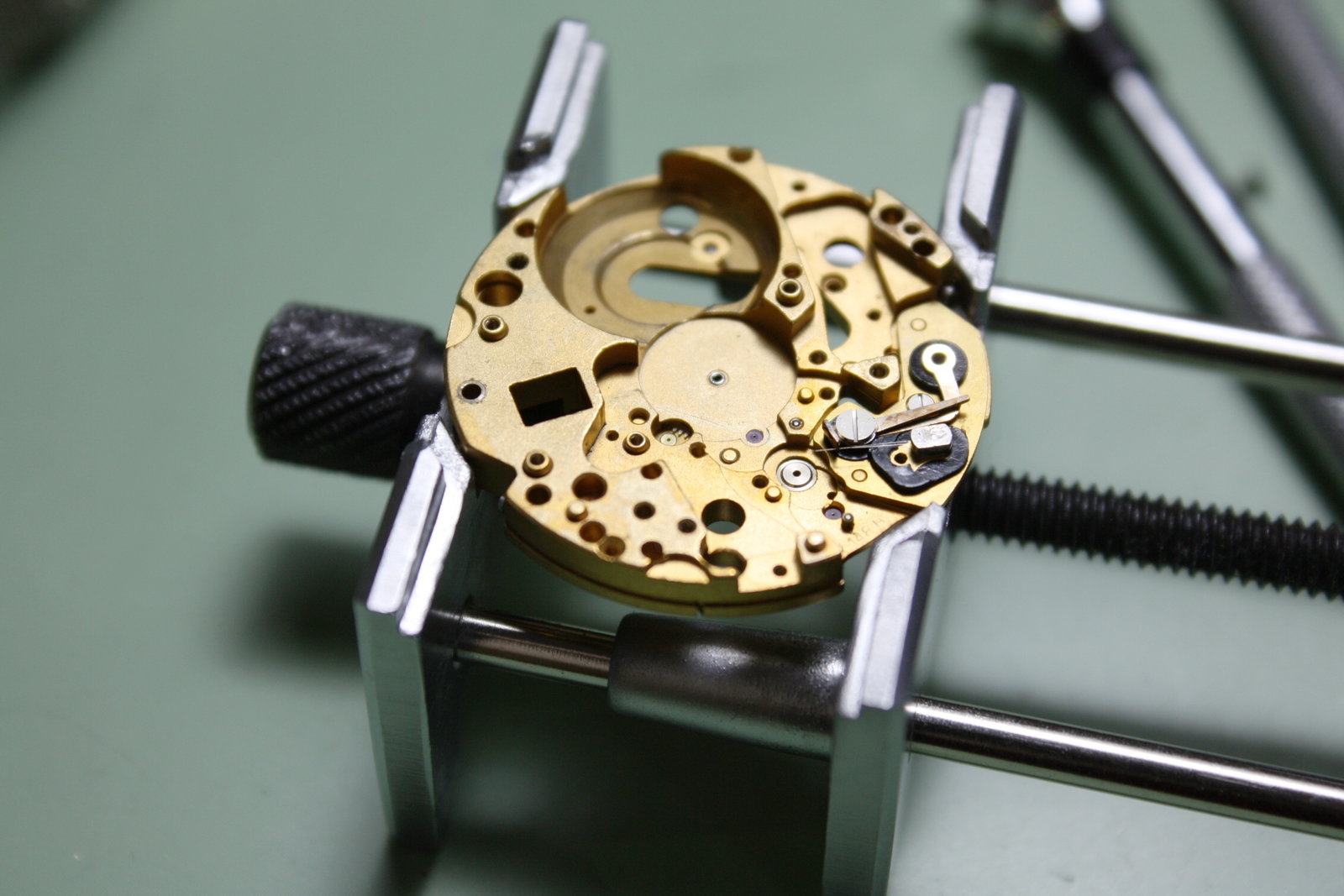

The teardown continues on the caseback side of the watch.

The coil (attention with the screwdriver here - it might be hard to get hands on a replacement coil...) and blue diode removed.

A peek under the wheel train bridge reveals just two wheels.

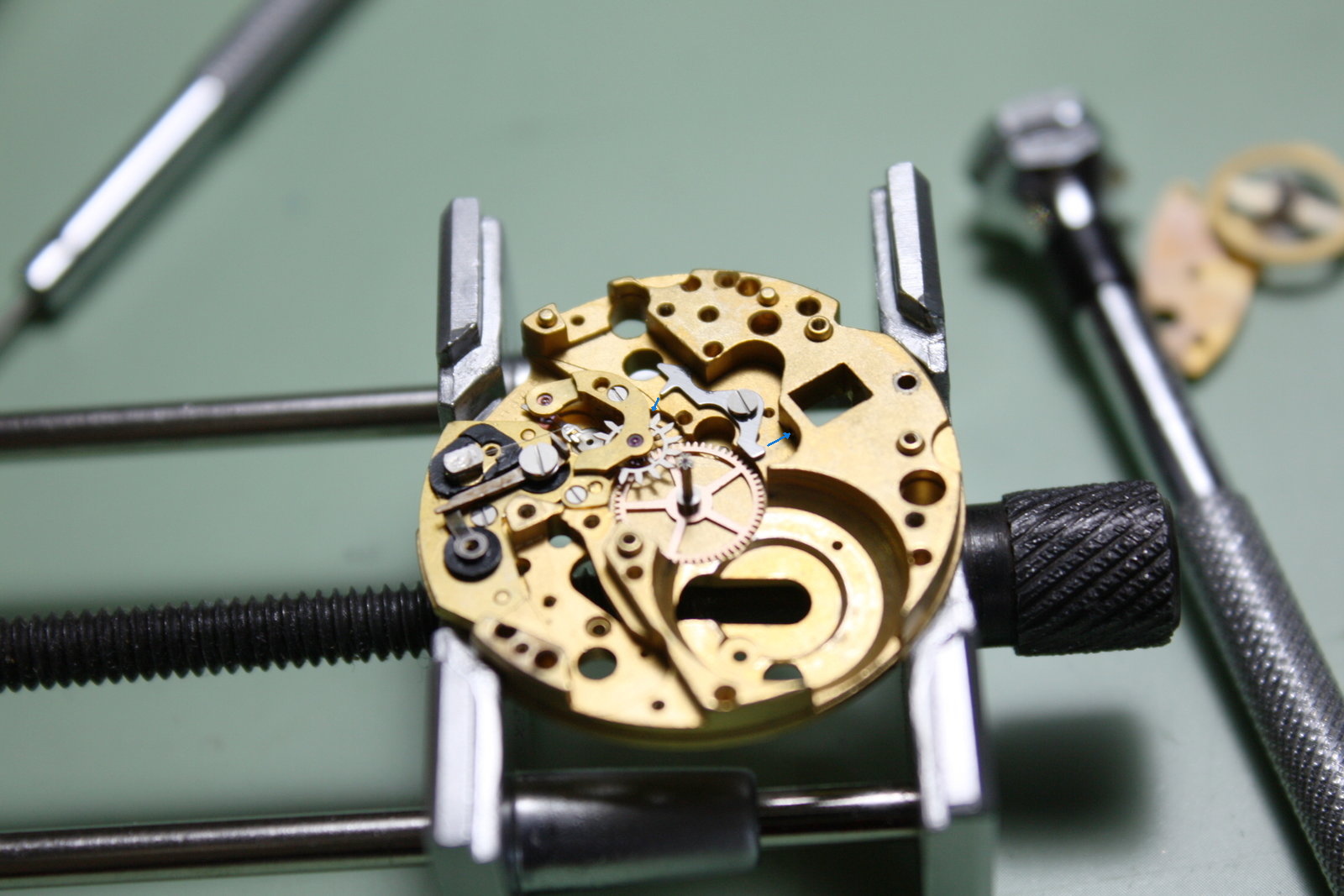

Balance cock removed.

The hacking feature in the center: "Crown out" means "hack lever in" (see blue arrows) - more on that later.

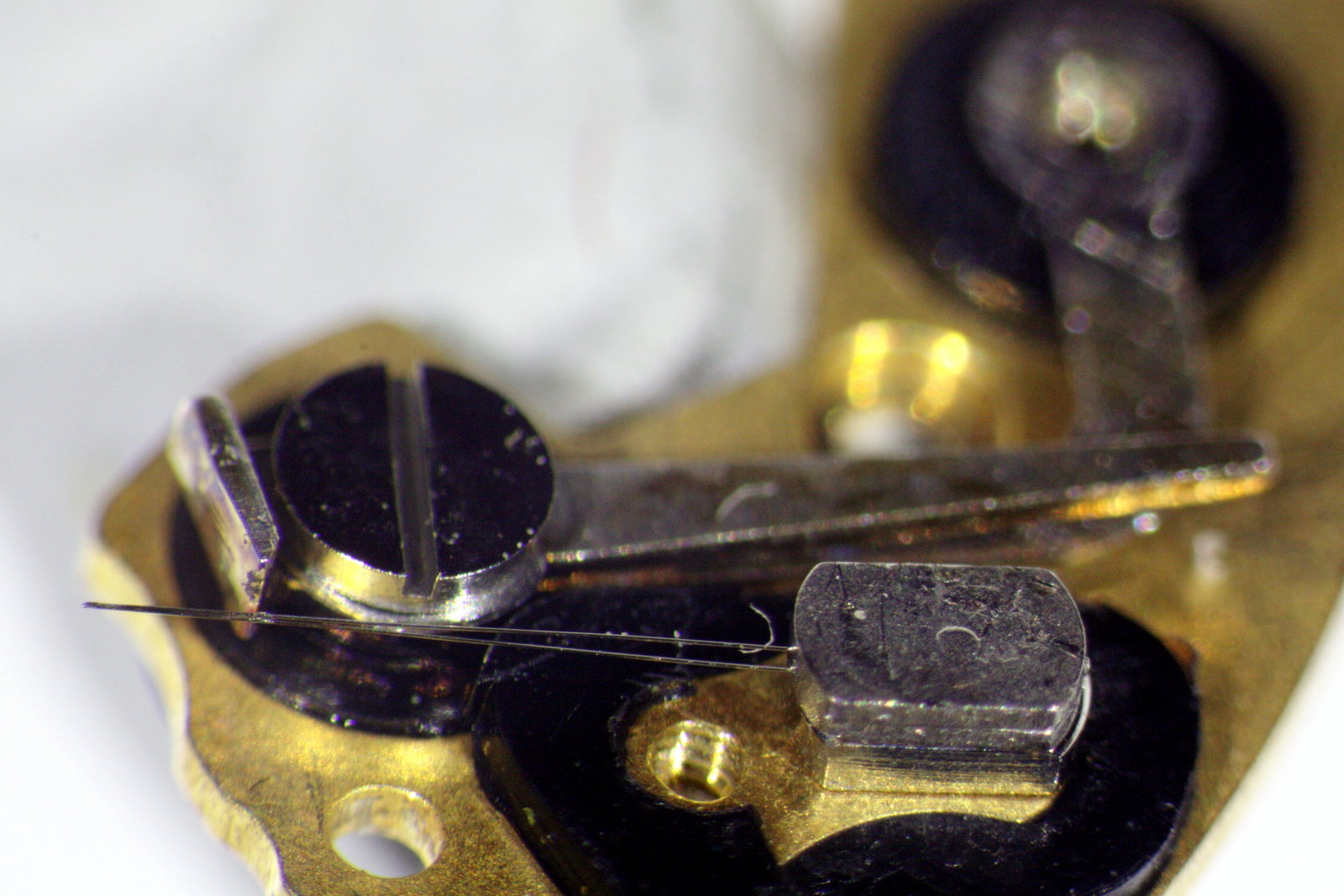

The last remaining part is the contact plate with the contact filaments on the right - the most delicate part of this movement and hard to even notice with bare eyes (bad watchmakers will always bend the filaments beyond repairability).

This one is in a perfect state of preservation (contact filaments forming the letter "V" and contact racket above perfectly movable) - good that the caseback was screwed-on so tight that no bad watchmaker ever made it thus far...

The fully disassembled movement before cleaning.

Case service

The case with crystal and bezel ring.

The plastic crystal is so thick that it should be possible to polish out all its stains.

The old gasket has hardened over the years and needs to be replaced.

I will only address the deepest marks on the case and try to regain some of the original polish

Afterwards the case looks somewhat better (dark shot to better highlight the polish around the crystal...).

A serious dive watch needs some serious lume on its hands and dial -> Luminova should do the trick.

Movement reassembly

I start with repopulating the baseplate.

The whole procedure is pretty straight-forward.

Dial side of the movement almost complete.

When the crown is put into setting mode, the spring-driven hacking lever (blue circle) engages with the escapement wheel (= EW) and the second hand stops immediately. There are also tiny magnets (orange circles) which ensure that the EW and anchor can only come to rest in defined states (essential for the working of this movement!).

Here the EW is back in its place and already covered with its bridge.

Reassembly continues...

Just one balance wheel missing.

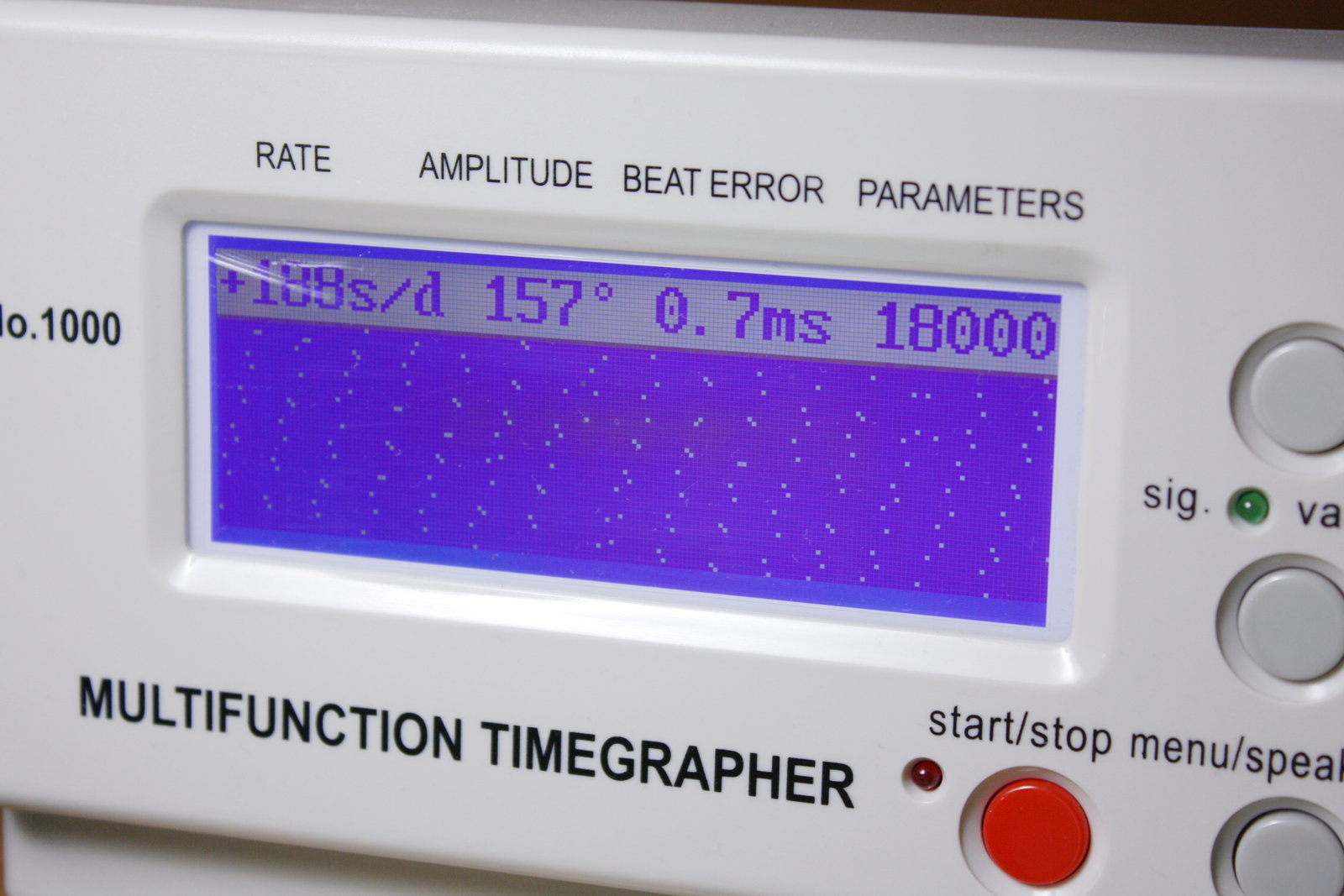

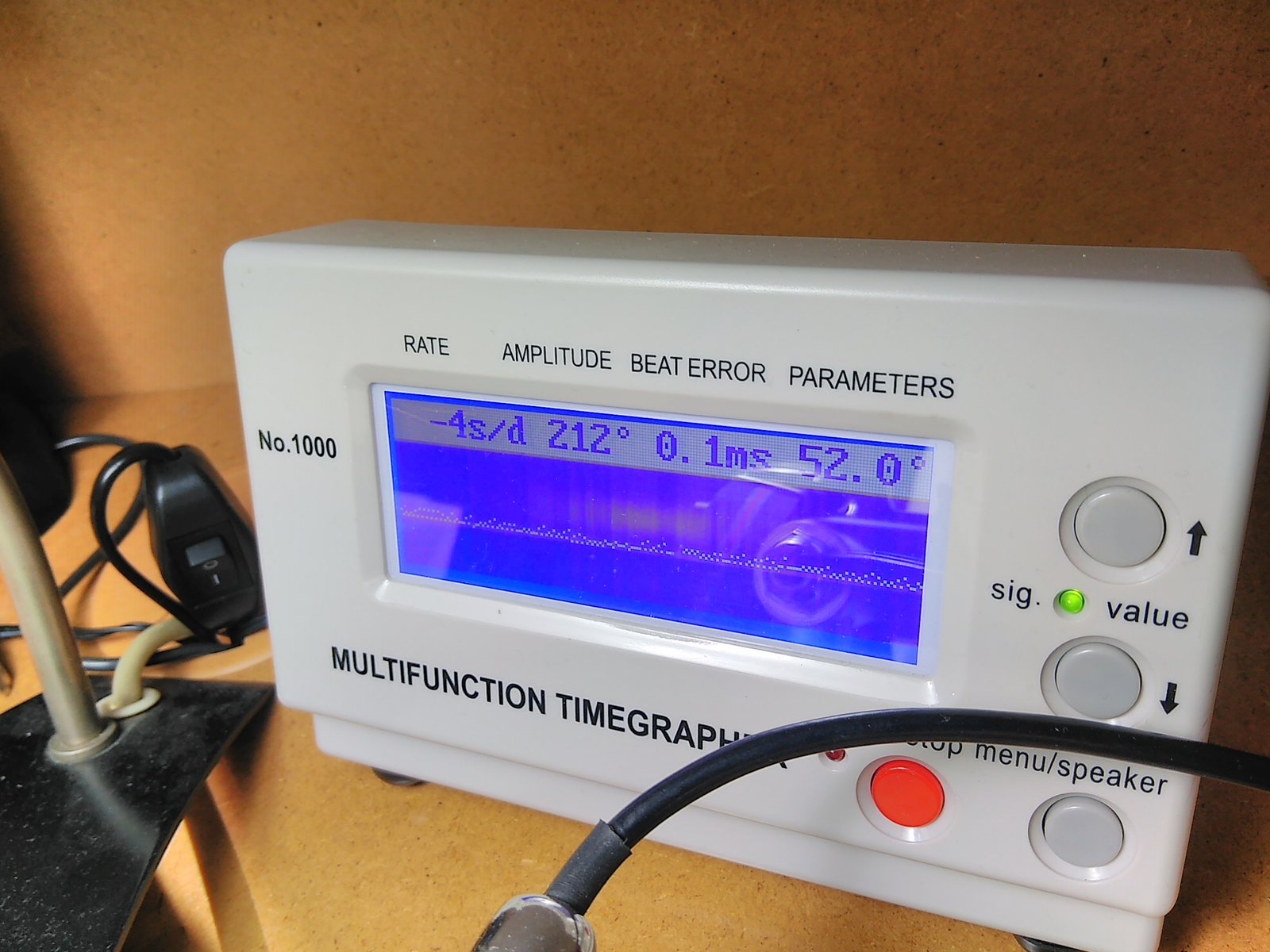

Done, time for a first test on the timegrapher.

We see a defined line pattern and still some huge gain of 52 seconds a day. The R184 is not so easy to regulate.

Dial refitted...

I have installed a new gasket to ensure watertightness in the future and with the movement back in its case, it should become a lot easier to regulate it.

Afterwards the watch delivers almost chronometer grade results.

And here the finished watch.

The new lume works all night long.

greetings noq2

Comments