Update 2015-07-06

2014-07-01

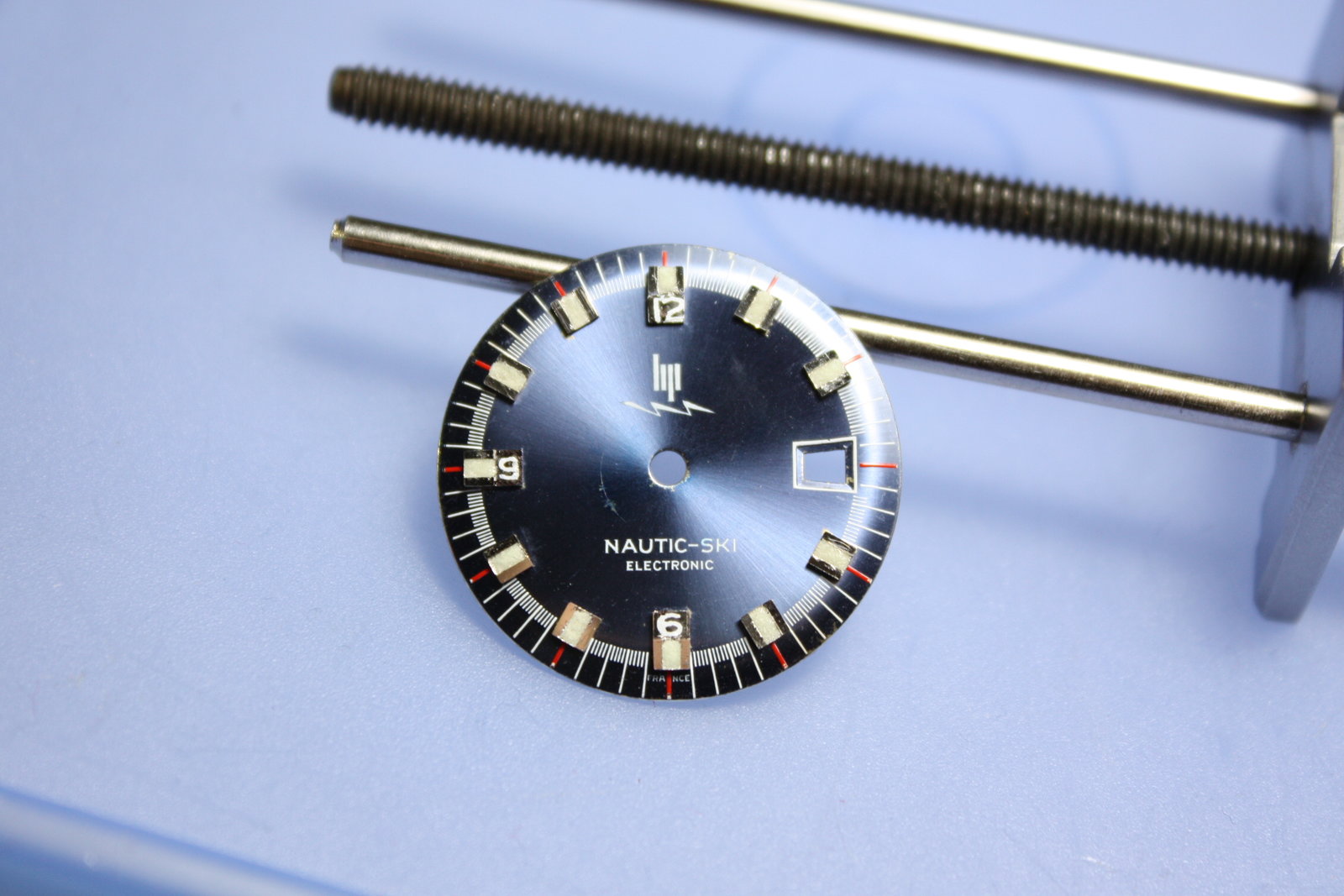

Time for a very special post for a very special watch: The first watch for divers with an electr(on)ic movement - the LIP Nautic Ski which was produced in France during the 1960s and 1970s. It is a watch that was used by Jacques Cousteau and his crew on their explorations and it was intended to be a real work(sea?)horse-watch. Together with its unique design variants it has thus become kind of a collector´s item. And here I have one too...

Starting situation

I got the watch for a reasonable price and it looks quite good from the outside (sadly the hour hand has caused some light scratches on the inner dial but I assume I can correct for this).

There is a small gap between the outer indicator ring and the dial (above 12 o´clock position) which is missing on the opposite side (below 6 o´clock position), this could be the cause for the dial scratches...

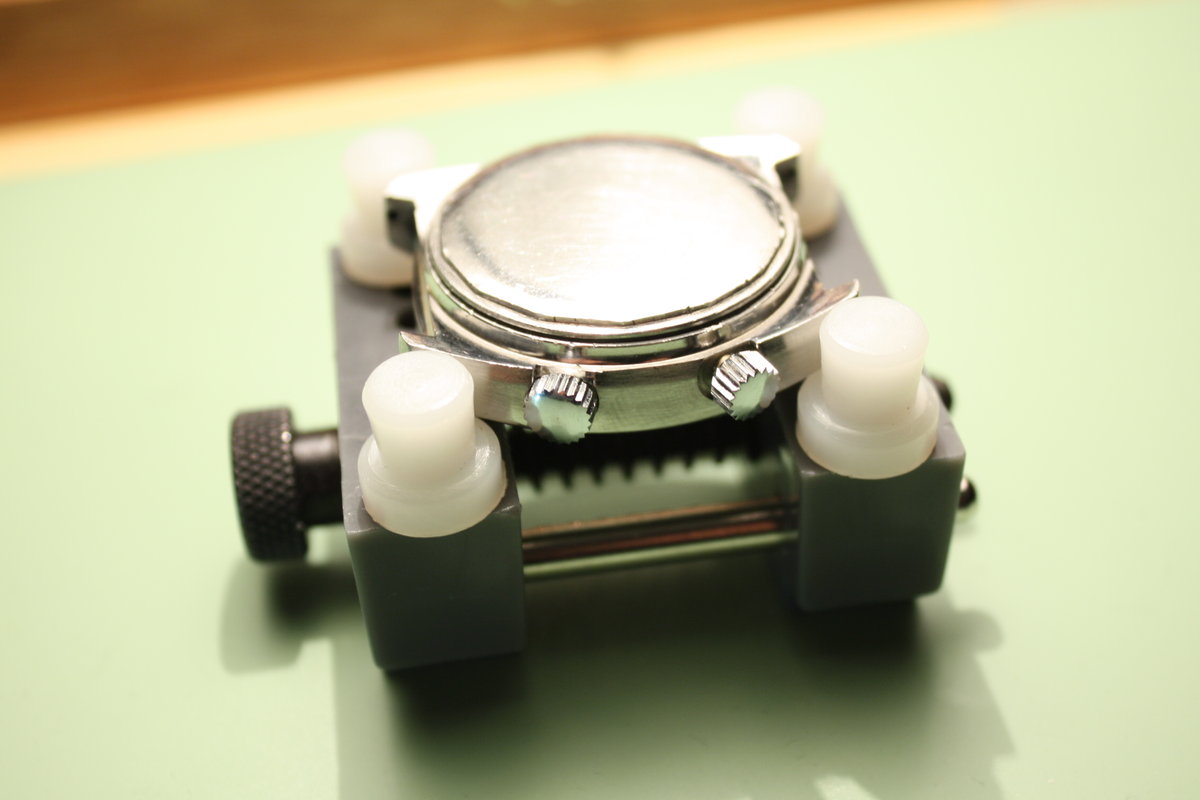

The case is tightly closed (underwater use!) and requires a special case wrench to get it open.

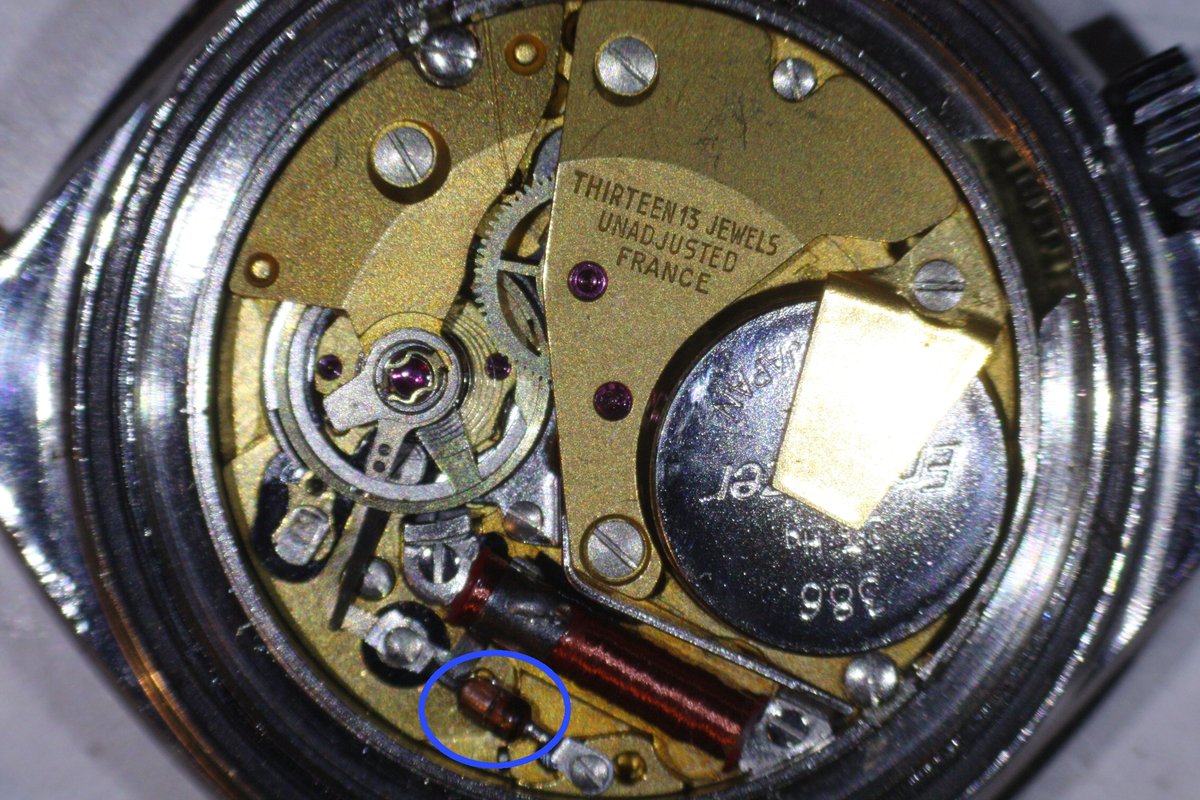

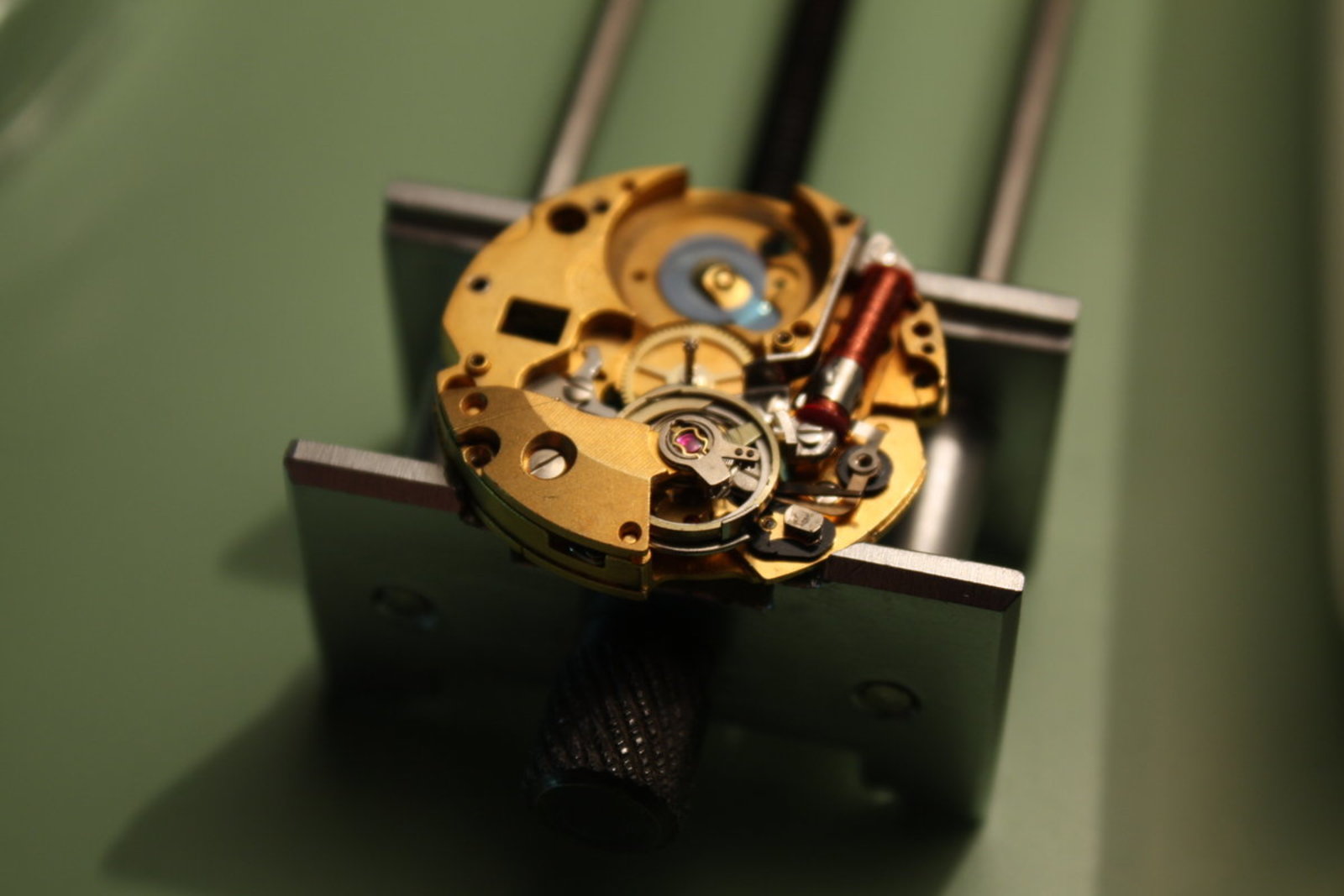

The nice-looking movement. It is a LIP R184 movement based on the LIP R148 which did not yet have a date indicator.

Some Details...

The movement is not really an "electronic" one as this would require the presence of at least one transistor (the first one featuring this tiny and then still quite novel device was the Bulova Accutron of the same era).

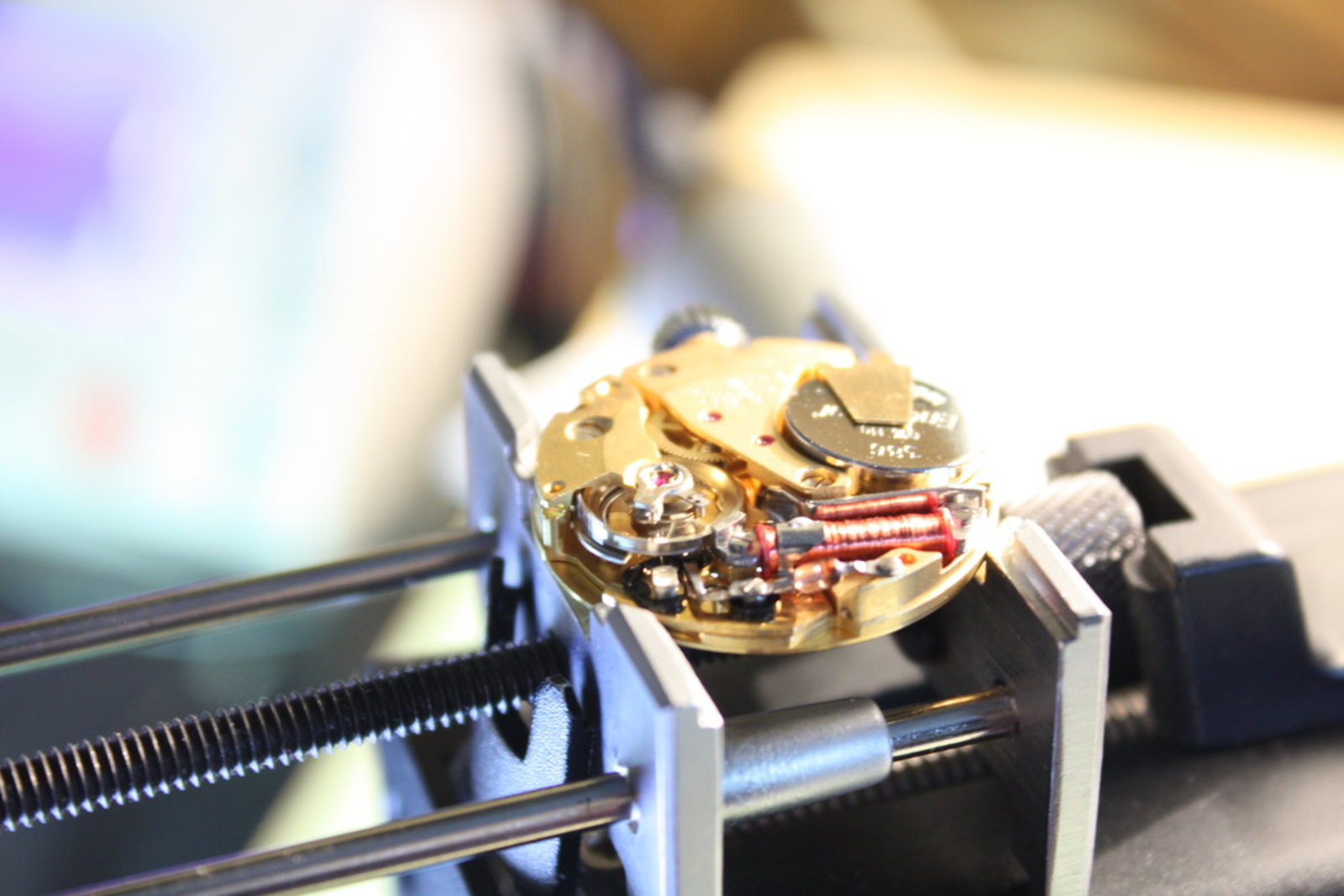

However, including the term "electronic" seemed to be a good selling-point per se back then and there was at least one semiconductor inside the movement for justification, as the LIP-engineers had to add a small diode (encircled in blue...) to act as a spark suppressor diode. It minimizes wear of the contact pins which switch the red-coloured coil on and off thus becoming a magnet and driving the oscillation of the mechanical balance wheel (on the left side).

The "Super Compressor" case was produced by EPSA (= Ervin Piquerez Société Anonyme) and features an engraving of the head of a deep sea diver. Despite the lack of screw-down crowns, the case allowed for diving up to 200 meters deep without letting water in (this equals 20 bar or around 600 feet). An advantage of the battery-driven movement was that winding it was not necessary thus putting significantly less wear on the crown gaskets in addition.

2015-07-06

A long time has passed...this is what happened in the last few months...

Teardown of the movement

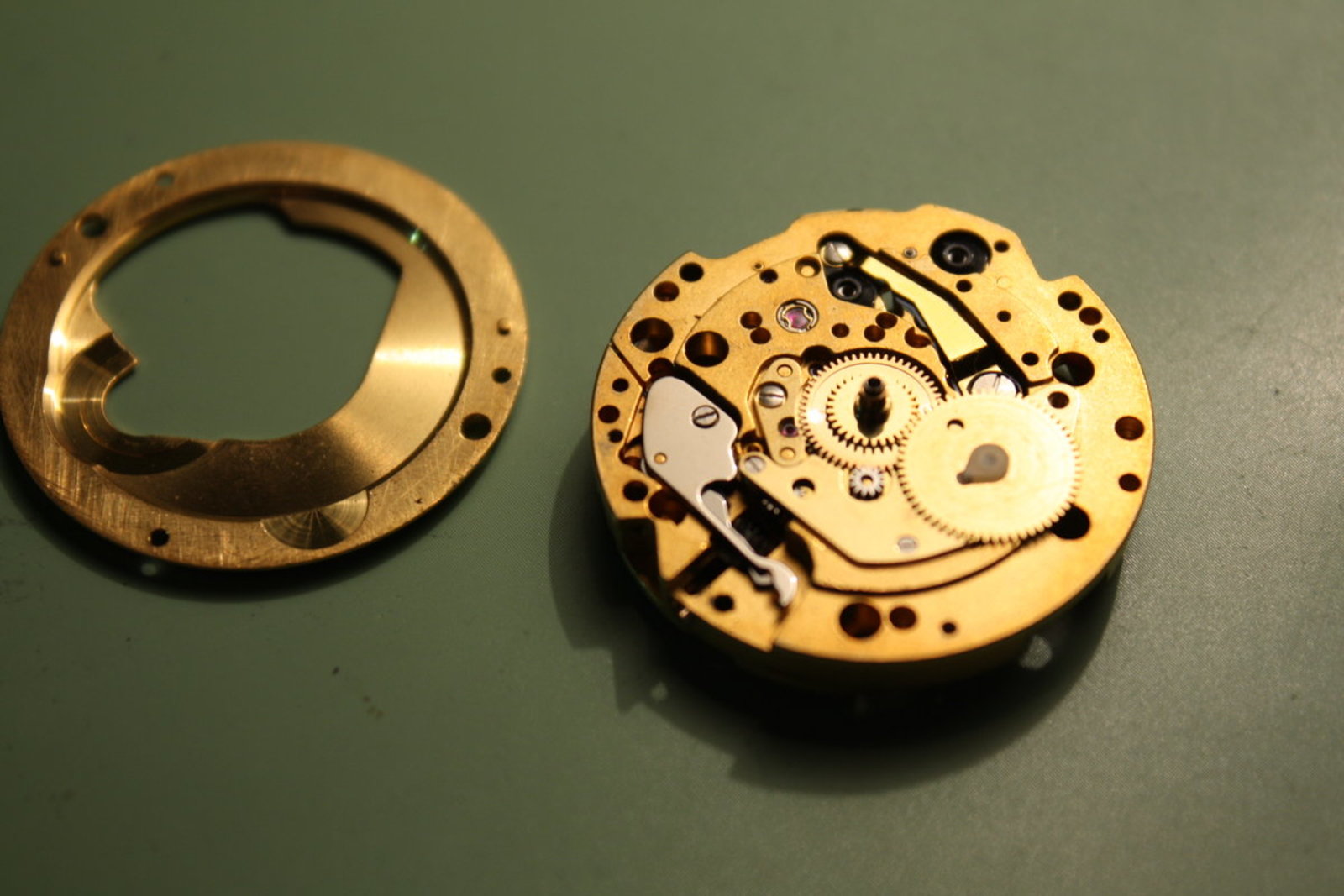

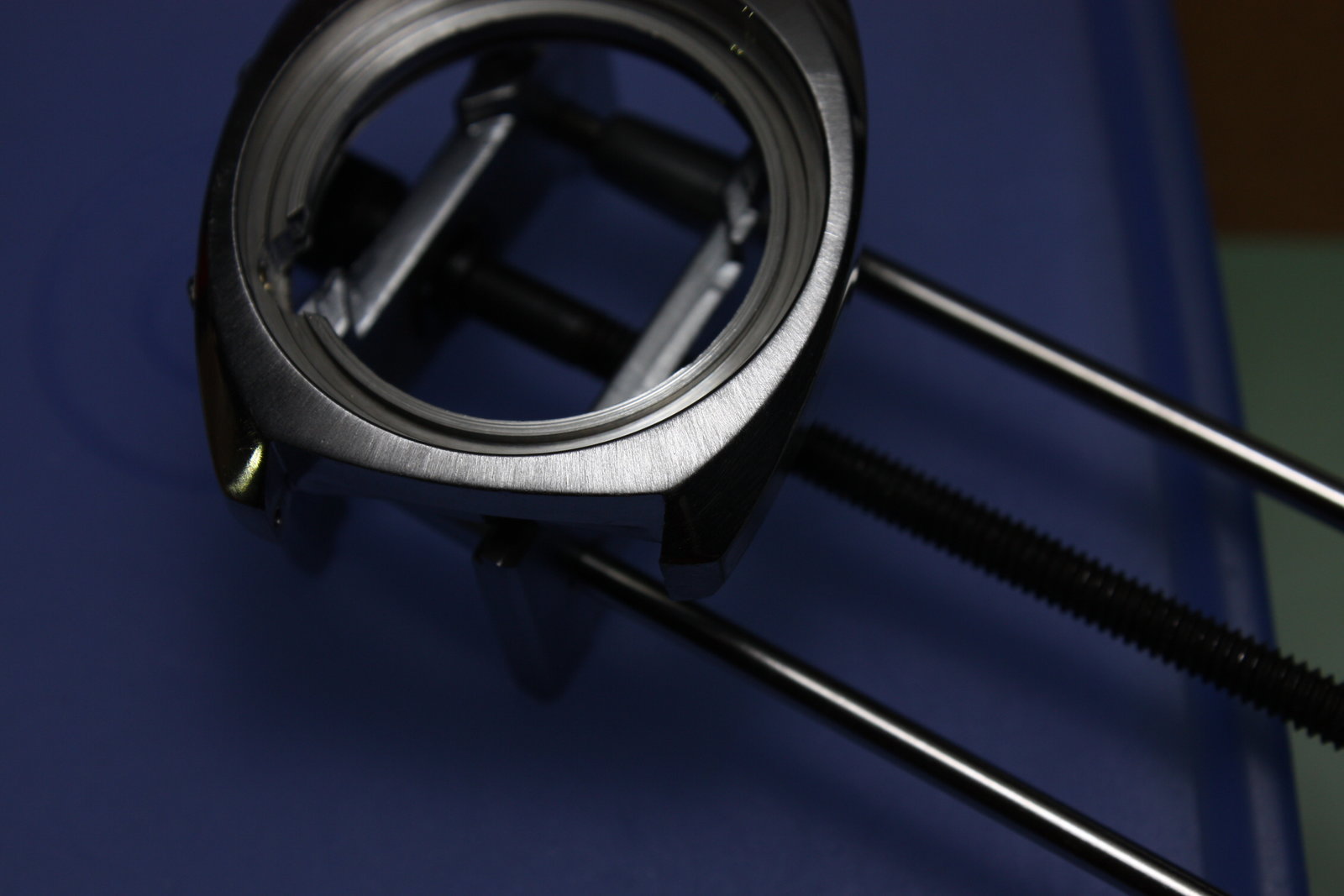

Case ring and crown with stem removed: The movement comes out:

Under the dial: The date disc is depressed by a washer:

And the disassembly continues:

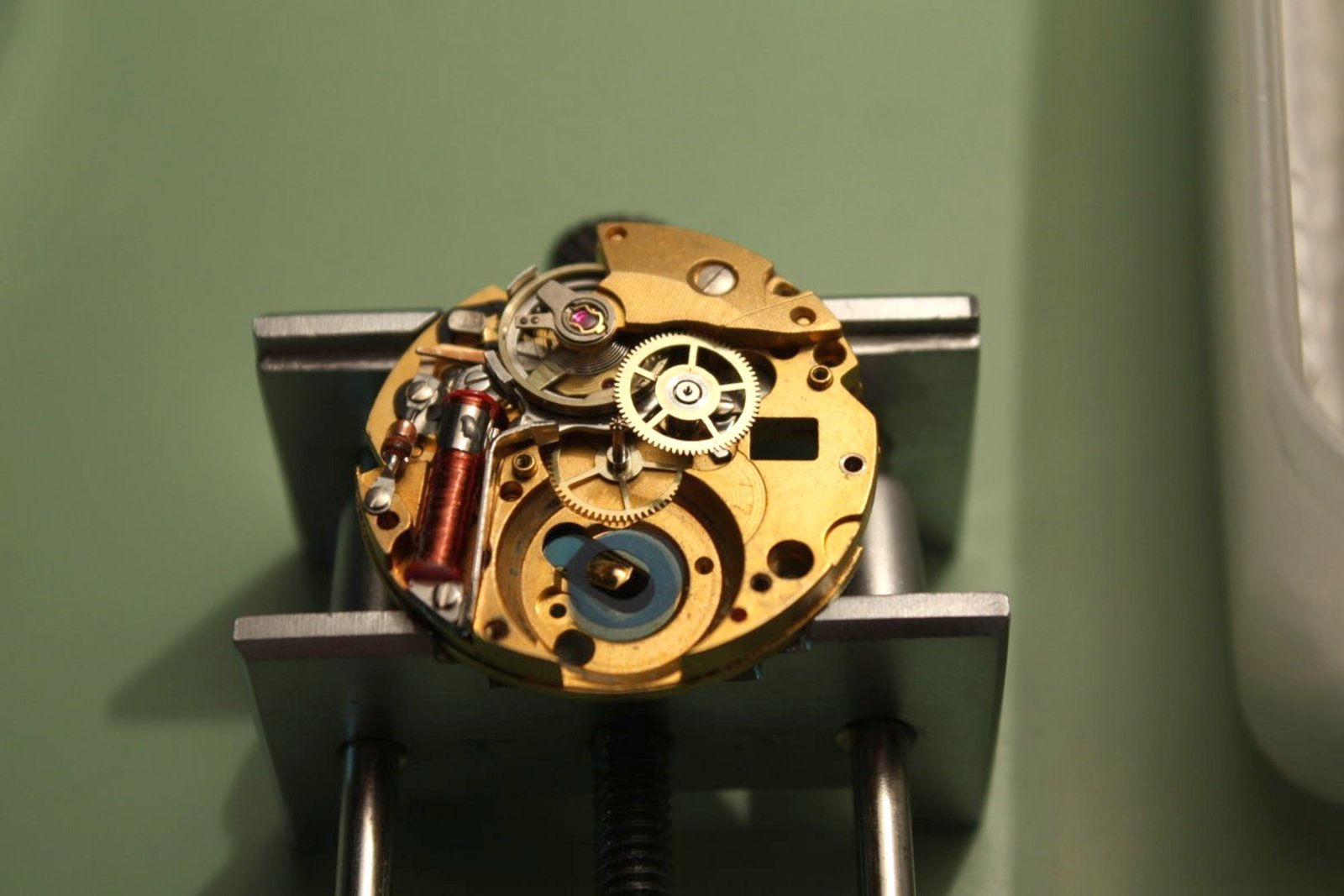

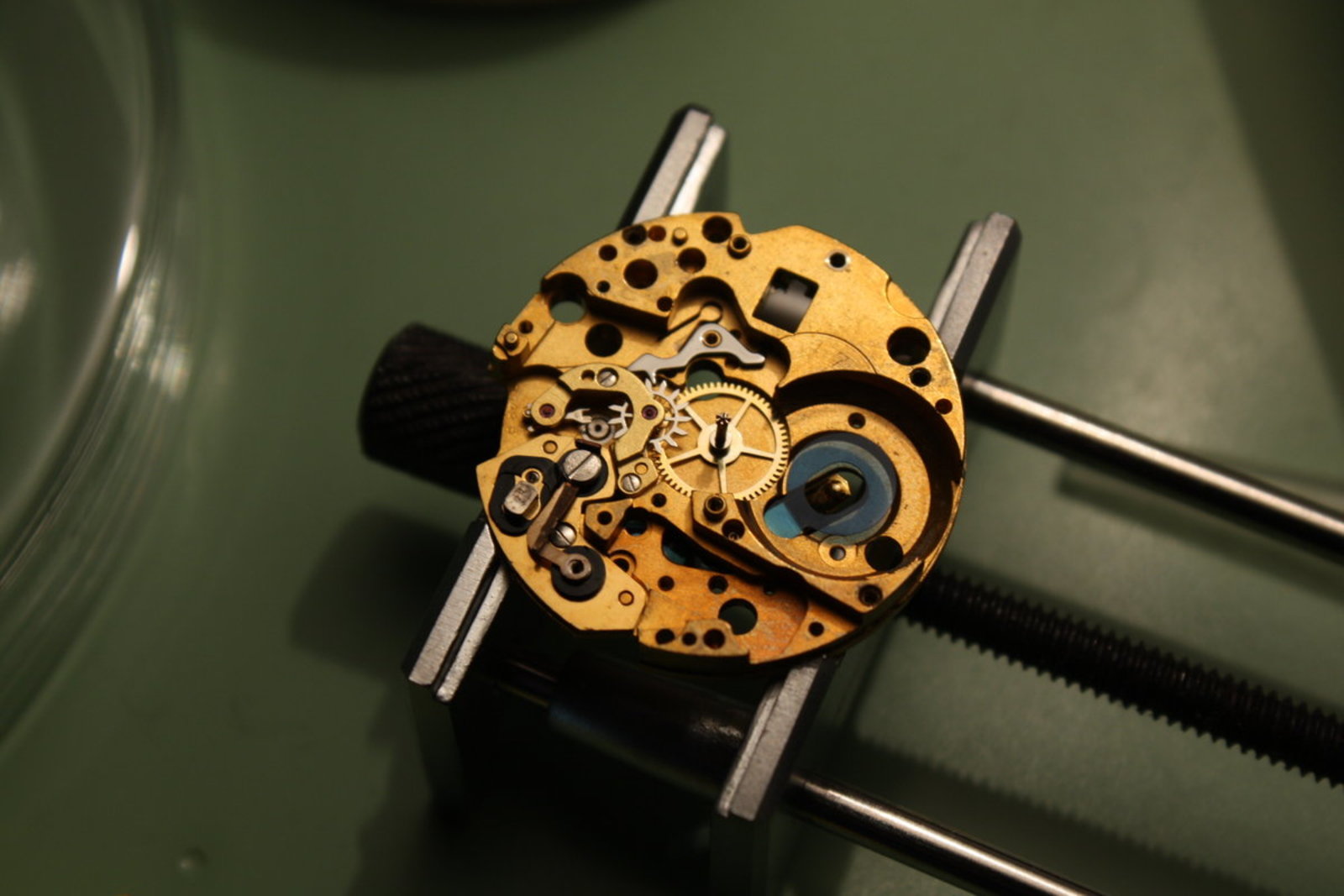

Next the backside of the movement:

Here, the balance wheel as well as the driving coil have been removed:

Below, the remaining baseplate:

And finally the parts before cleaning:

The disassembled case, interestingly the crystal is a two-piece construction with a lower metal ring. Maybe the crystal is not original and has been replaced at some point in the past? As it holds tight and allows for easy-setting of the bezel ring I let it stay...

Cleaning and reassembly

I clean the watch movement in the usual way, here the cleaning baskets with the already cleaned parts:

Putting the pieces together was nothing special in this case, I just checked all the parts for faults (there were almost none) and lubricated were necessary. One thing I particularly liked about this movement is the friction wheel (next picture) which allows for setting of the time. I assume this durable spring-based way of doing it generates much less wear as the typical cannon-pinion solutions.

Finally the completed movement on the timegrapher - more on this later, as it took me some time to get a decent amplitude and timekeeping from the movement.

Repairing the dial

The dial was in a bad shape at first. I started with removing some dust and imprints and I relumed the hands and indices:

Resoldering the broken dial feet, was somewhat critical / unsettling as I had to keep temperatures low and limited to their exact positions to not damage the dial to a point of not return...

I used some blue lacquer to cover the scratches on the dial (they are barely visible now under normal daylight conditions):

Case finish

I tried to get back to the original sunburst pattern as close as possible - not without success as the following photo shows.

The finished case and polished crystal:

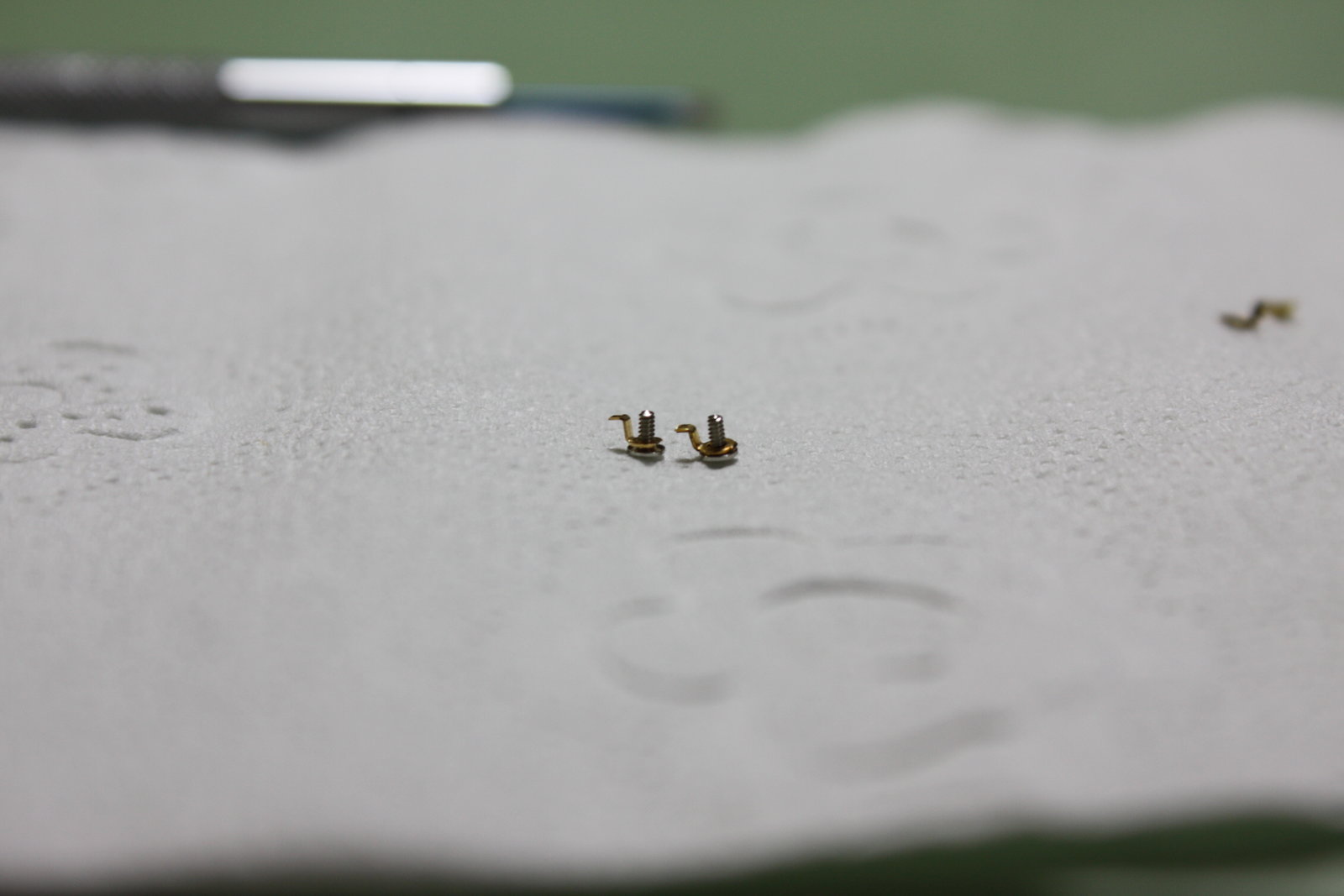

To fix the movement position in the case I had to replace the missing retention clips. I "killed" to old hour hands for this purpose:

The two clips with screws. Not perfect but it should do the trick...

Finishing the project

Time to put the movement back in the case:

Regulating this watch was an awkward job - in my opinion the movement is much less service-friendly as that of other electric watches. You have to ensure for...

-

a correct alignment of the impulse pins (two tines, delicate as the pawls in tuning fork movements; see the picture below)

-

a correct distance between coil stator and balance wheel rotor counterpart

-

a correct positioning of the balance wheel regulation

Overall, I could not get above a 208° amplitude (which may otherwise be normal due to the uncommun construction of the movement - I assume the "anchor" in this movement is just there to prevent overbanking and to deliver sound signals which conventional timegraphers can interprete...any comments?). Timekeeping was excellent, though, with a gain of only around one minute throughout several weeks. Here the watch with a new Nato strap:

And here in darkness to show off the relumed dial and hands:

greetings noq2

Comments