This is an Omega Speedmaster Automatic chronograph (Omega reference nr. 176.0012) - quite rocked but at least it´s running...

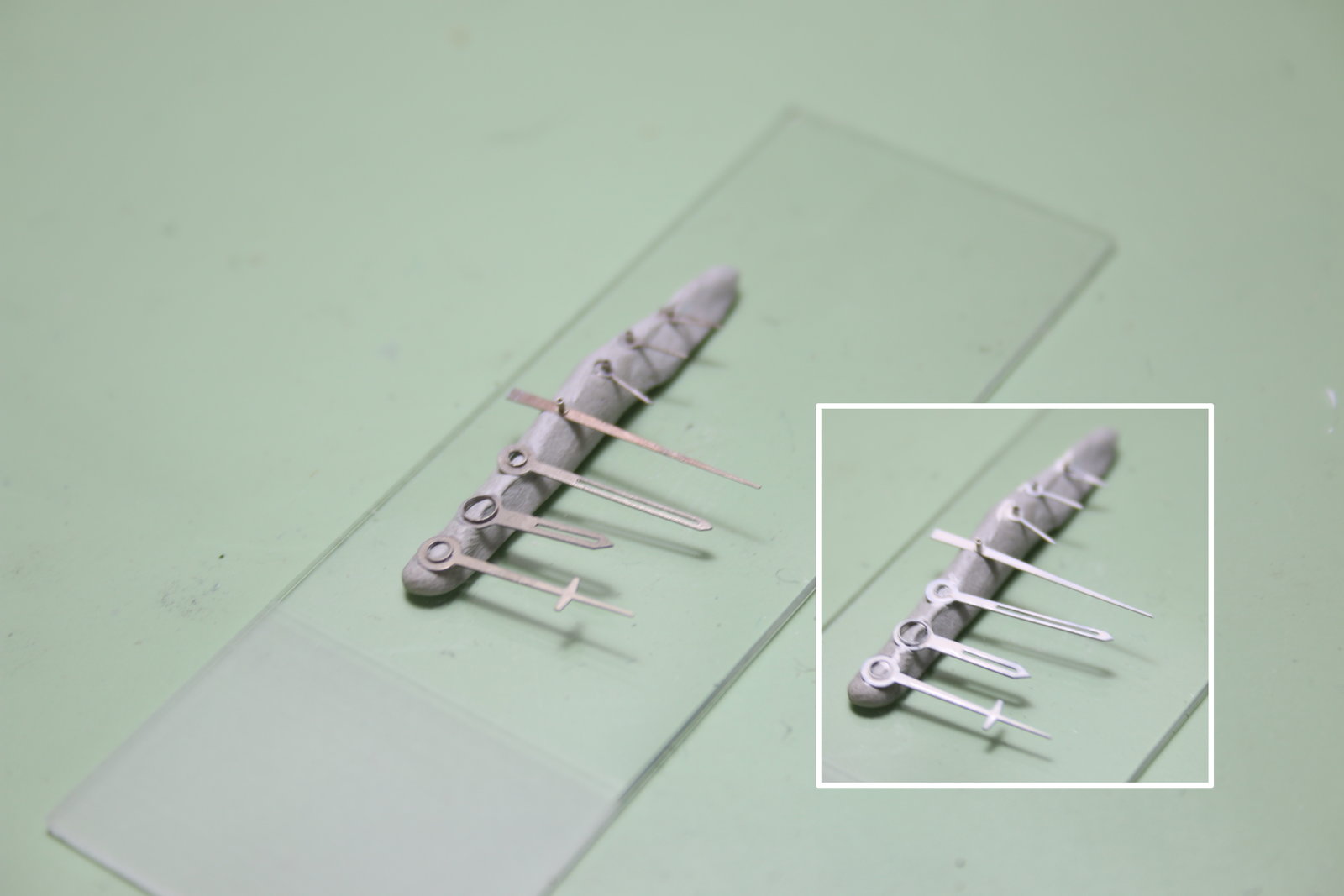

The hands have lost their lume - as the powder is not visible anymore, we can assume it has been removed in a workshop. The spring of the chronograph reset pusher seems missing, too.

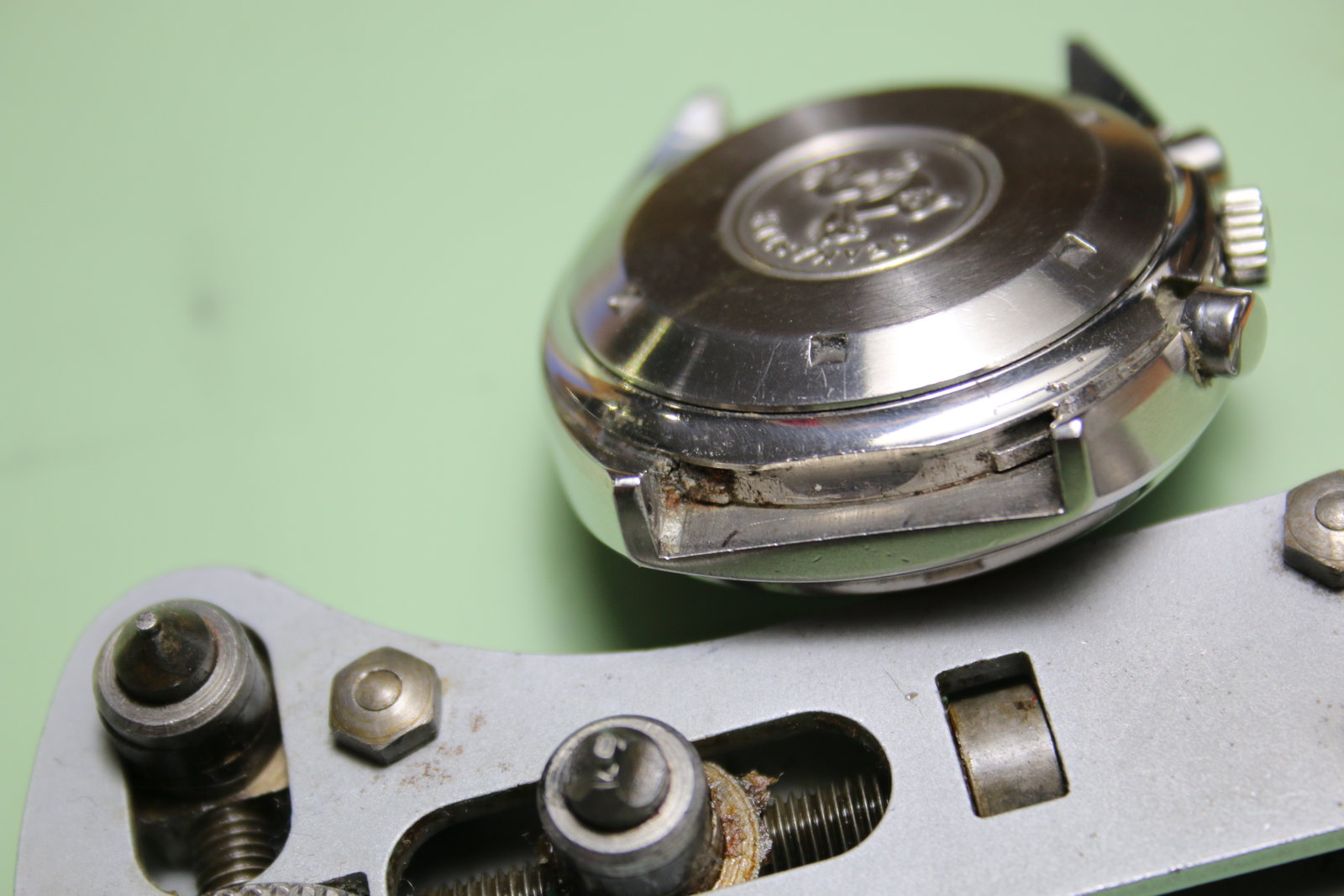

The caseback with it´s hippocampus logo.

First traces of rust, there is more to come...(promised)

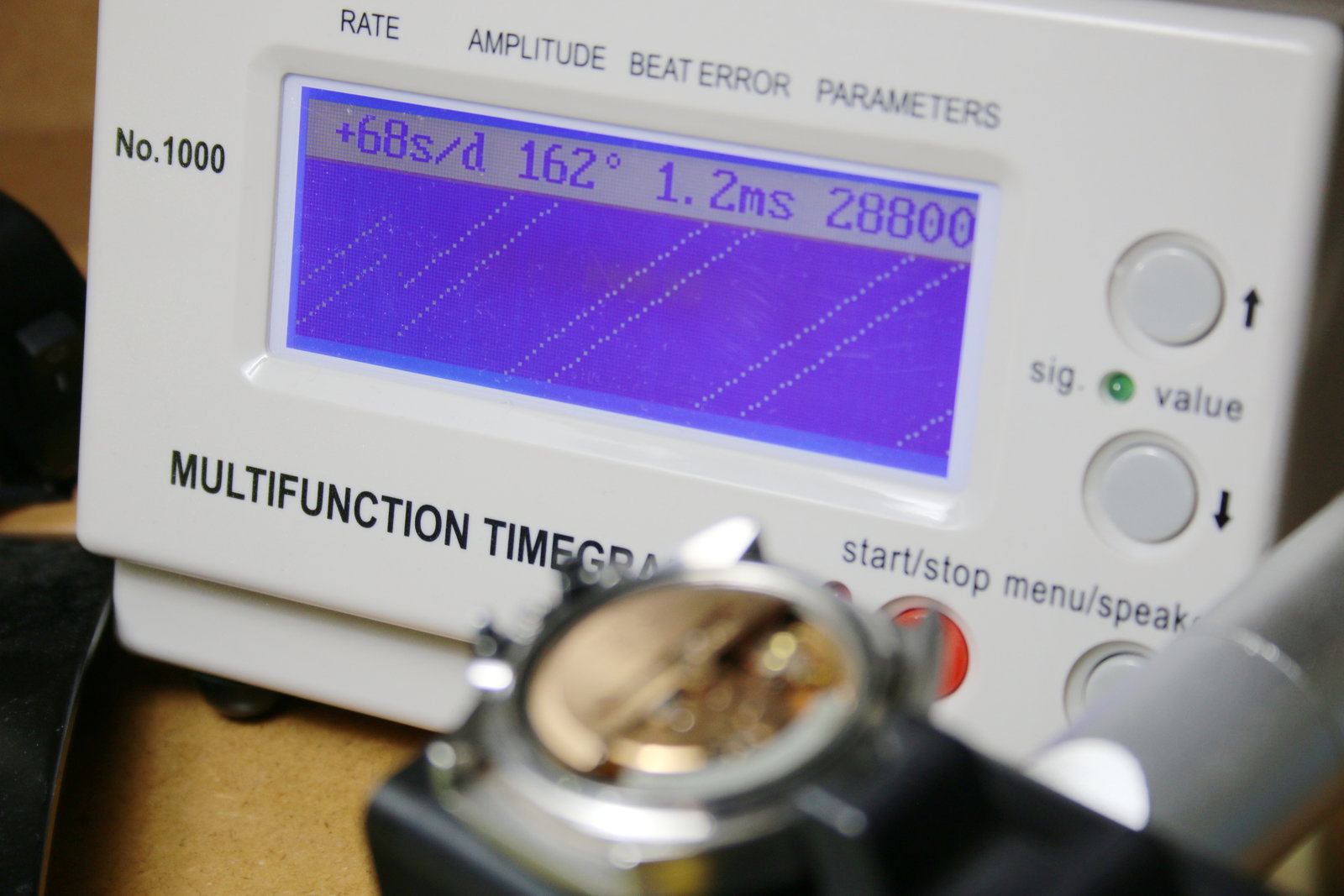

At first glance, the Omega 1045 movement (a modified Lemania 5100 actually) looks okay...

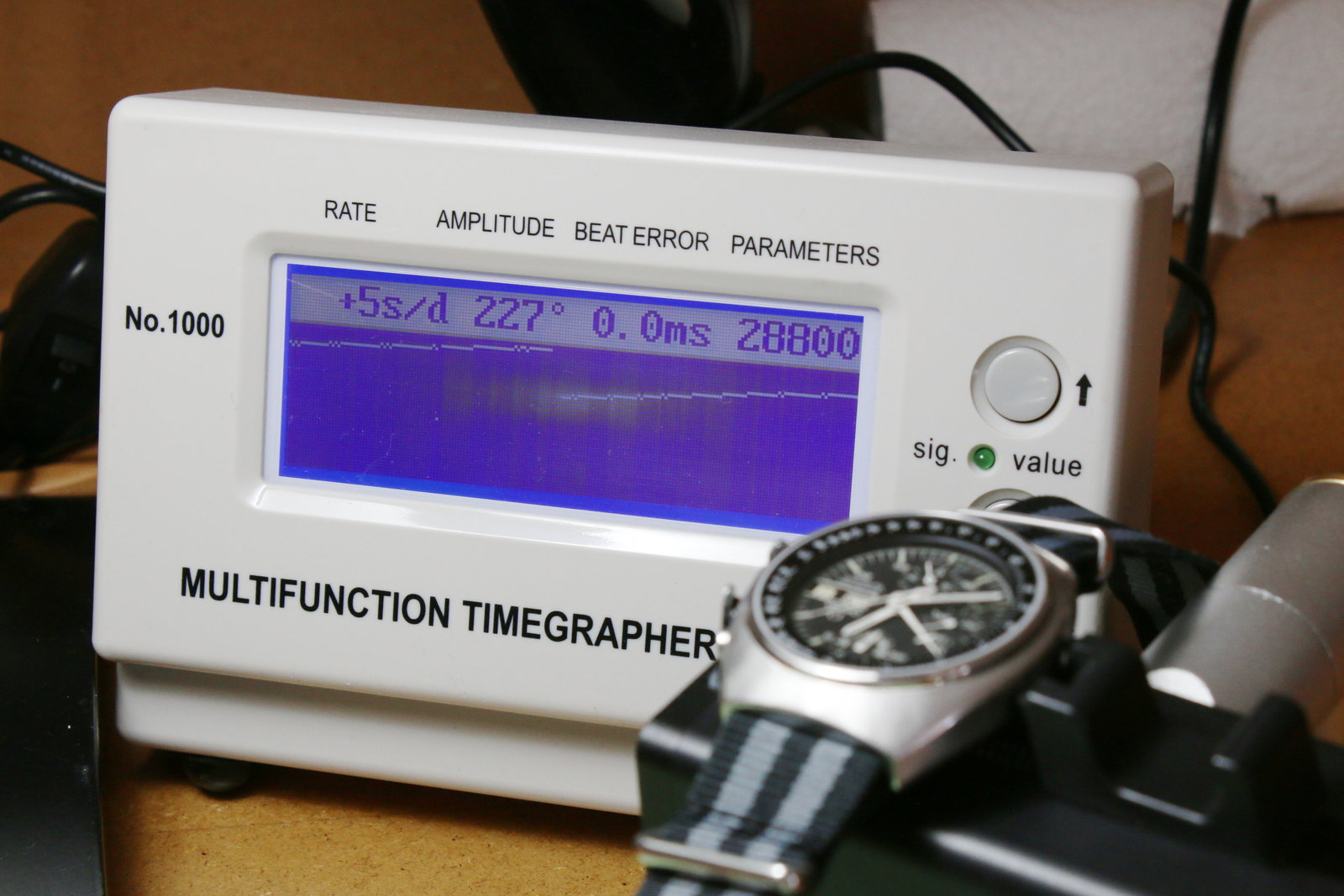

...the amplitude not so much. A service is highly indicated. Especially if we go into detail:

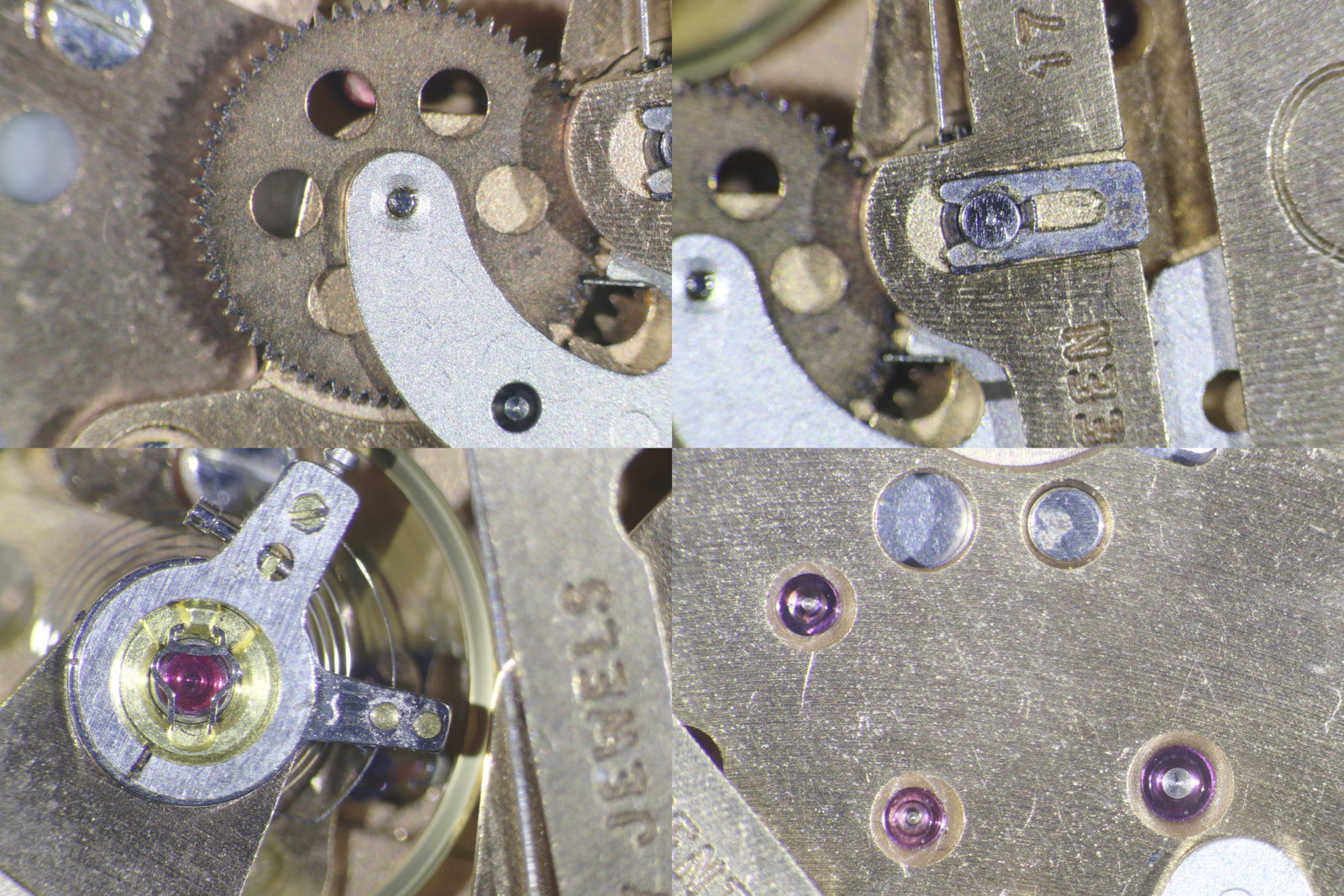

We find traces of old lubricants and dry bearings (e.g. of the balance wheel).

Teardown

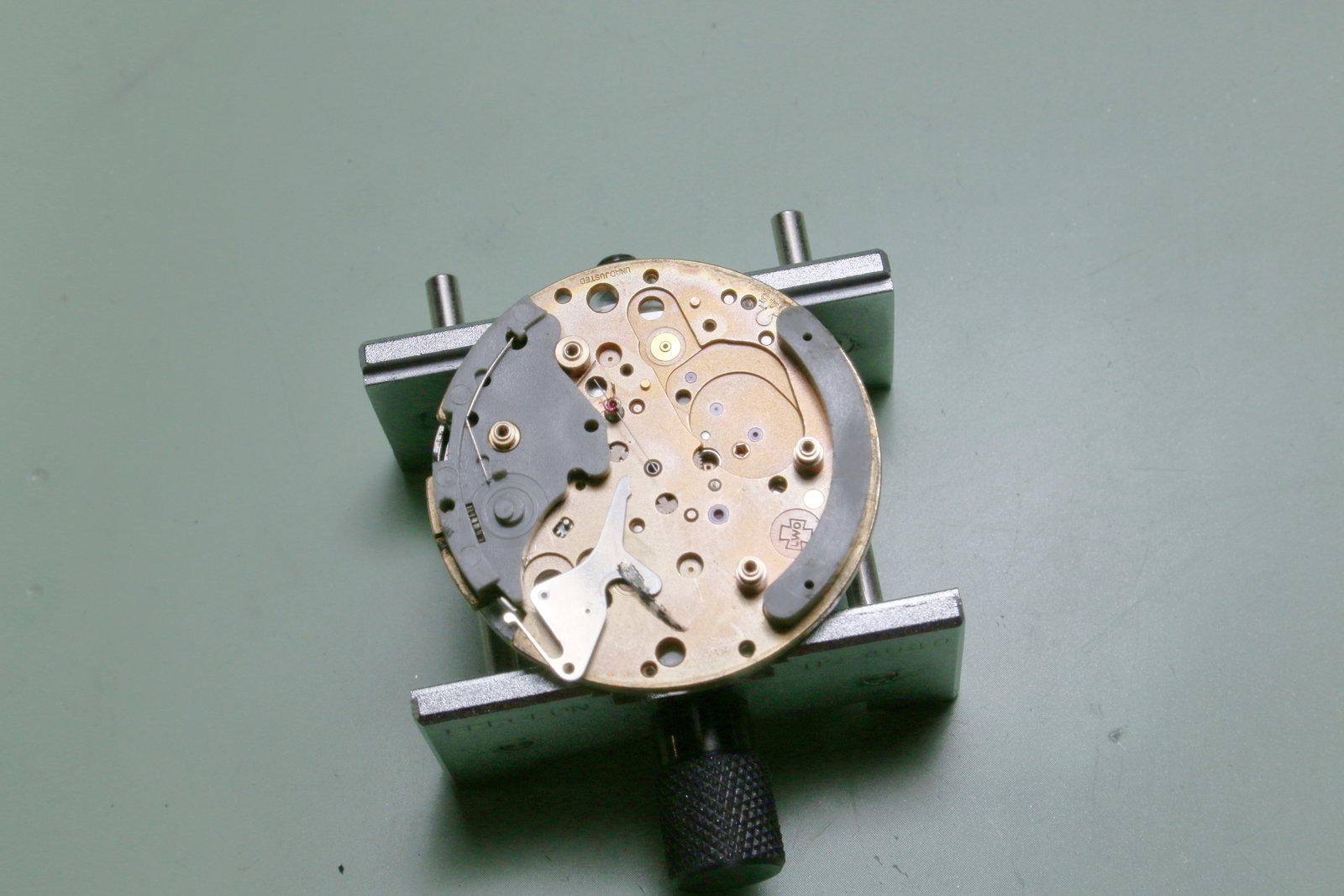

Rotor removed. The automatic winding mechanism of the Lemania 5100 works only unidirectionally btw.

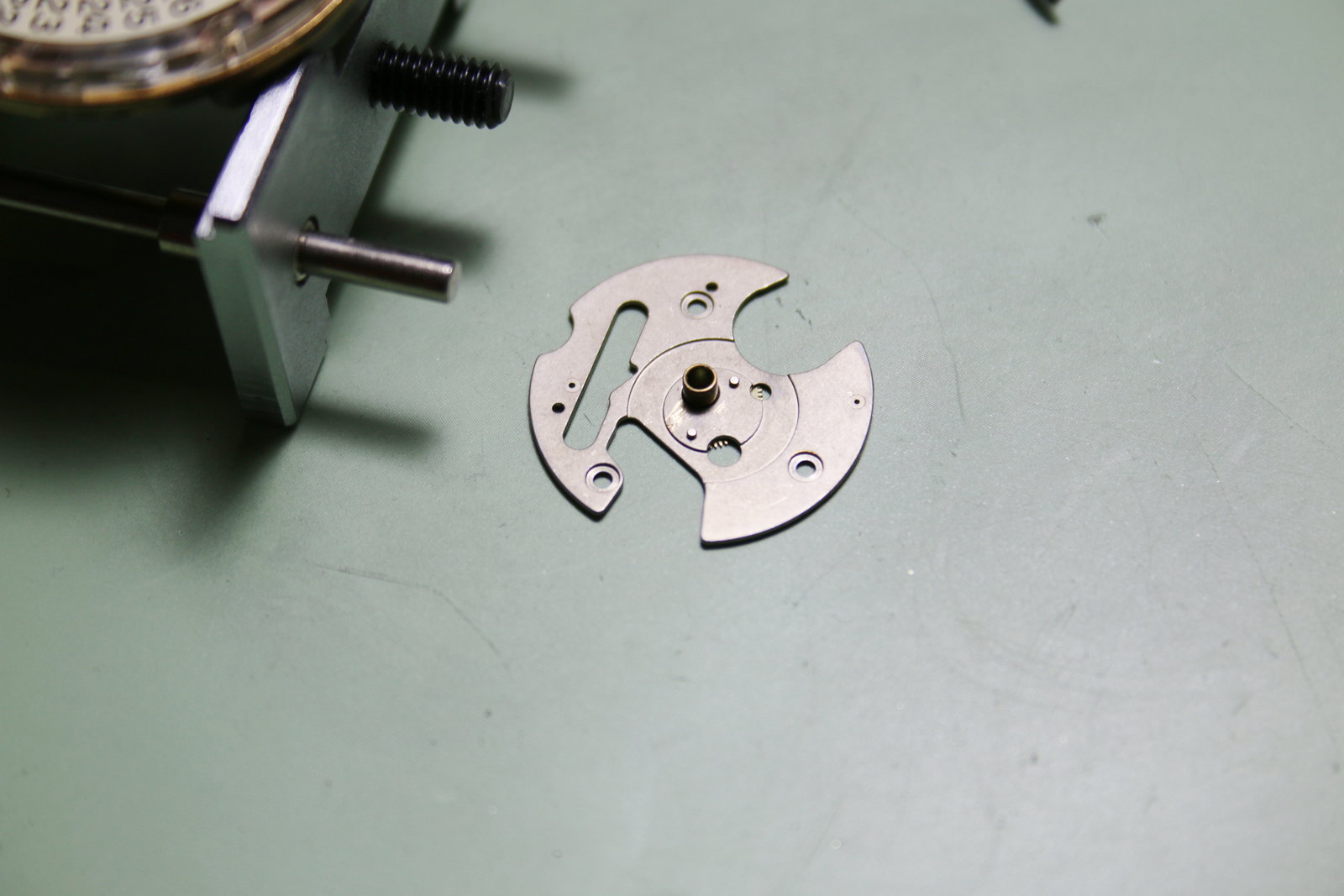

Automatic bridge removed.

I remove the crown and stem and the movement comes out...here we have a clear view on the stained dial.

Case and removed crystal.

The Lemania 5100 had some cool "unique selling propositions" if you like the term. One is its day-date function.

Another one is a slide-in / slide-out barrel which is very service-friendly.

The balance cock is more like a bridge that rests on the plastic stem cock (i.e. the grey part on the left). The plastic btw is an acetal-compound and called "Delrin". It can be machined easily and precisely and yet it also resists chemicals and high-temperature (consequently it was often used in space flight and aviation).

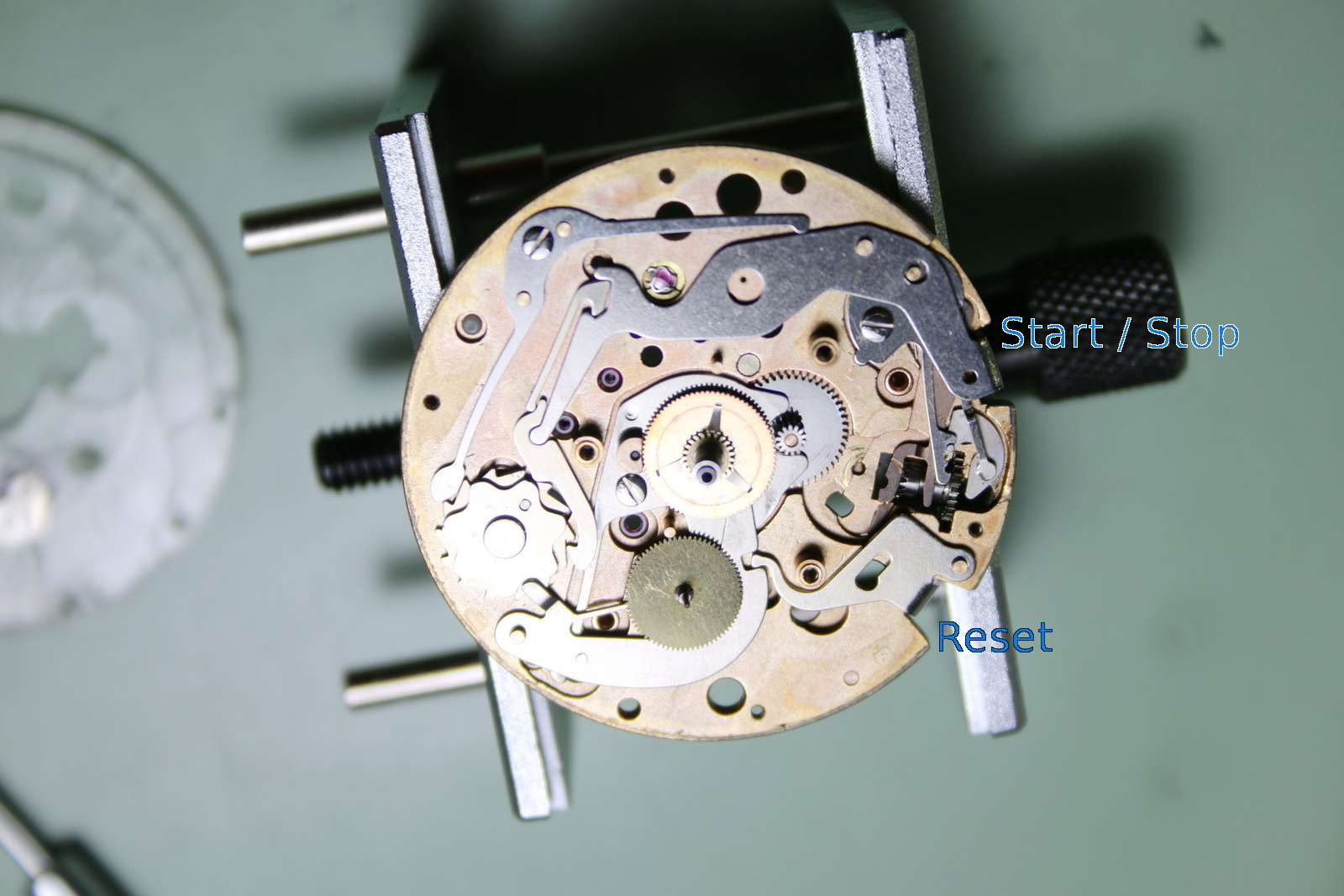

Under the 3/4 plate bridge. The coupling runner and its yoke (blue encircled)...

... these two make the heart of the chrono mechanism.

The exposed wheel train and in the center: The chronograph runner which indicates the elapsed seconds.

We move on to the dial side of the movement.

Under the day indicator and its guard.

Date indicator guard taken off (hour wheel adhering...).

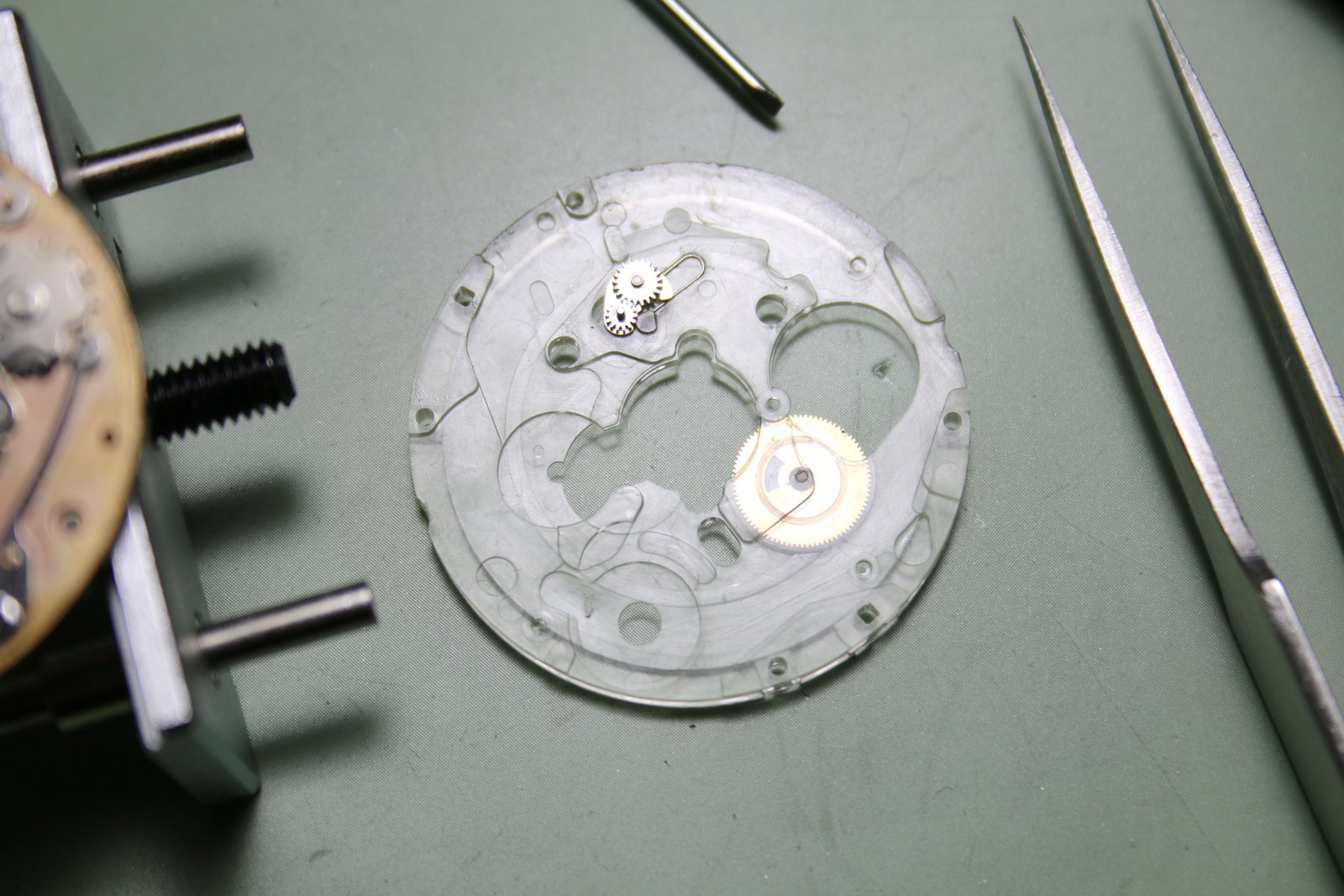

We find a multilayer structure with lots of plastic. Good, but only as long as nothing breaks or melts.

With the date indicator away the whole inner workings become visible.

The date indicator support is no Delrin part - it´s really cheap plastic (indeed somewhat "broken by design", but when the movement was designed the spare parts were readily available).

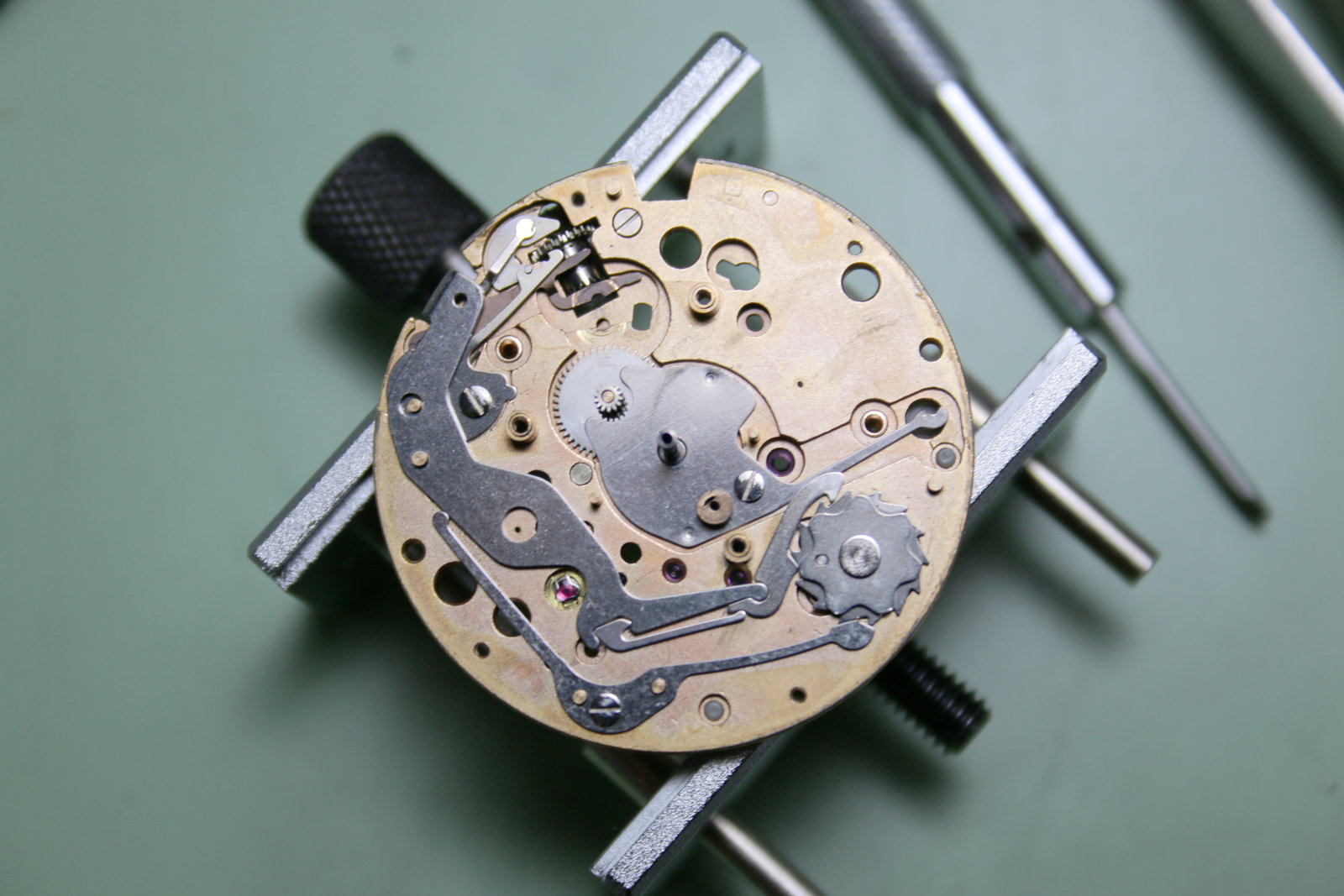

One might call this "the lever-level". Pillar wheel with hammer cam on the left.

The lever construction is simple but pretty effective.

Further detail shots incoming...clearly this movement shows many signs of neglect and abuse:

Stem cock (a), the rusty winding stem (b), one of the pushers (c) and the scratched date indicator guard (d).

The barrel drum with mainspring and the ratchet wheel.

The movement in parts.

The removed stem cock is basically dead...the previous watchmaker has used superglue (!) to hold this part in place (really, there is no excuse for this :-/ ).

Beware: Now it gets really ugly...the case (like in "The case" the horror movie that never was):

The case is two-parts actually. In my case (in my case...understand...) corrosion had caused the two parts to actually become one. And to make the situation even worse, the previous watchmaker has again used (nooo, not again...but sadly, yes) superglue (moron...). I had to exert an enormous amount of force to separate the two parts (some hundred kilograms) and the mix of superglue and rust was also quite challenging.

Time to shine (or simply cleaning all the movement parts).

Reassembly

I start with the mainplate.

The new stem cock in place (what an expensive little part, I wish the superglued one had not been that fubar...).

Setting up layer...

...after layer... with just the right amount of lubrication and NO superglue this time...

Almost done...

The rotor gets an all-new bearing.

Finished movement. Next comes the dial.

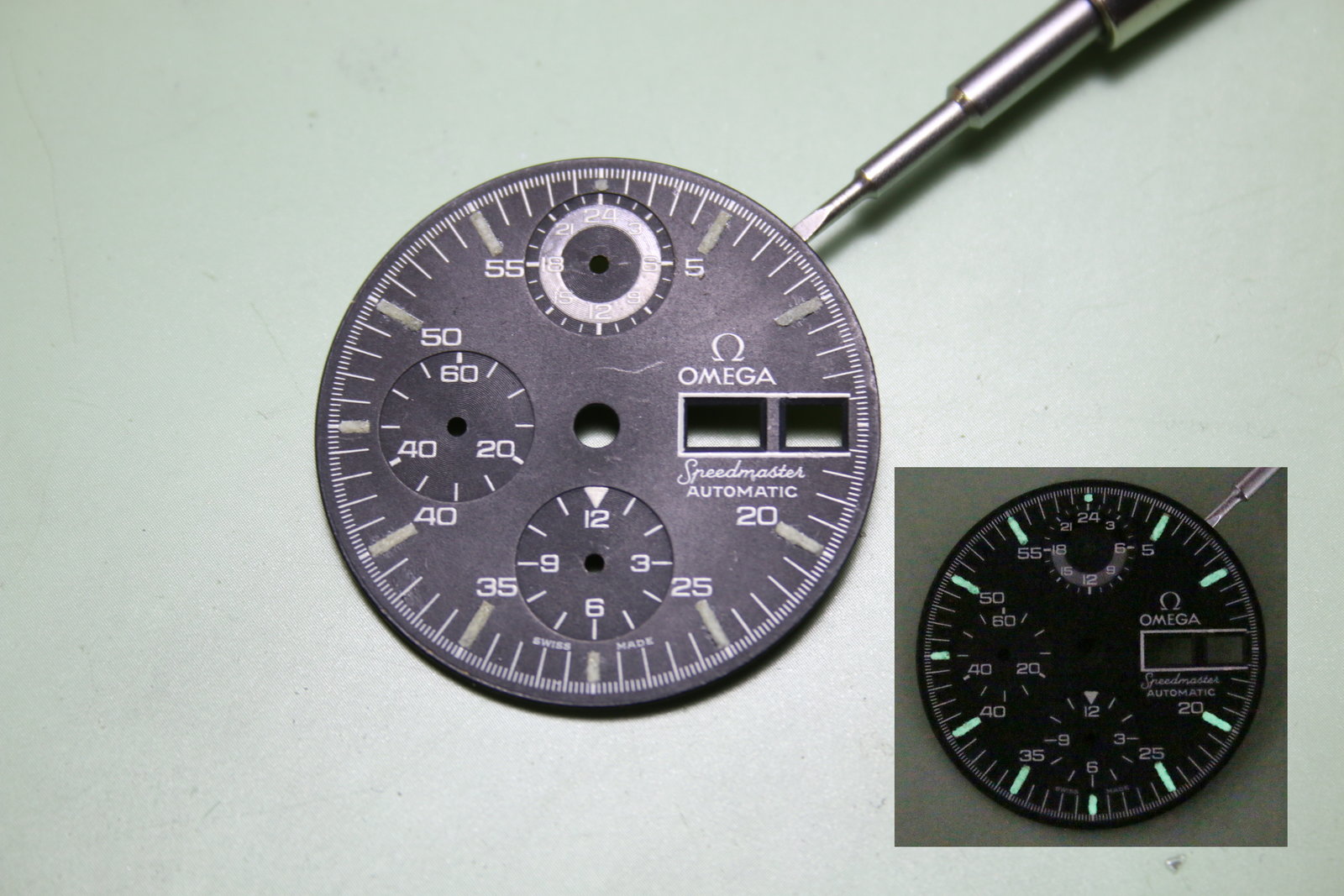

I can´t remove the superficial defects. But what I can do, is repaint the fine white lines and apply a "monolayer" of Luminova over the old hour markers. This way the dial will retain its patina but it will glow in the dark.

The hands get repainted.

Movement with dial back in place.

Okay, I take pride in the words "This is really the same case!"

Rust removed, light scratches removed where possible, pushers repaired, new crystal and a new crystal gasket.

Time to come together. Blue encircled: The previous watchmaker has polished the lugs so hard that the spring bars might break out. Sadly, laser deposition welding is not an option (not yet?).

The new winding stem and crown.

The performance on the timegrapher. Five seconds plus per day and a perfect beat error. The amplitude is still somewhat low, but I decided to wait until I find a new mainspring for a reasonable and not sky-high price (as it is exceptionally easy to replace it, this won´t be much of a problem when the time - pardon - the mainspring comes).

The watch on a Nato strap (this way it will not fall to the ground if the spring bar should come out one day...). That´s it :-)

...

Uhh, what about the chrono second hand (= CSH), this is NOT genuine !!!11

Okay, here comes the explanation. It is a second hand from a different movement (ETA 2824-2, I have of course kept the old CSH). But heck, why?

What I hate about the 176.0012 case is that the rare and expensive crystal stands out for almost a millimeter in the original case design. This makes it extremely susceptible to scratches (just check out the first picture of this article if you can´t believe me). The reason for the additional height was the long arbor of the original CSH. By using an ETA second hand and taking some material away from the crystal gasket, I could fit the crystal in perfectly. Thus its rim is well protected by the case and gasket, admittedly at the cost of some originality. Too much for purists, maybe, but remember that the changes are reversible and where we were coming from here :-)

Finally, a night shot to calm those down who don´t like the "flat crystal solution".

greetings noq2

Comments