Not sure if anybody ever documented something like this online. Today I swapped a defective integrated circuit (= IC) of a Accutron 2210 tuning fork movement.

Dead coil, good IC vs. good coil dead IC

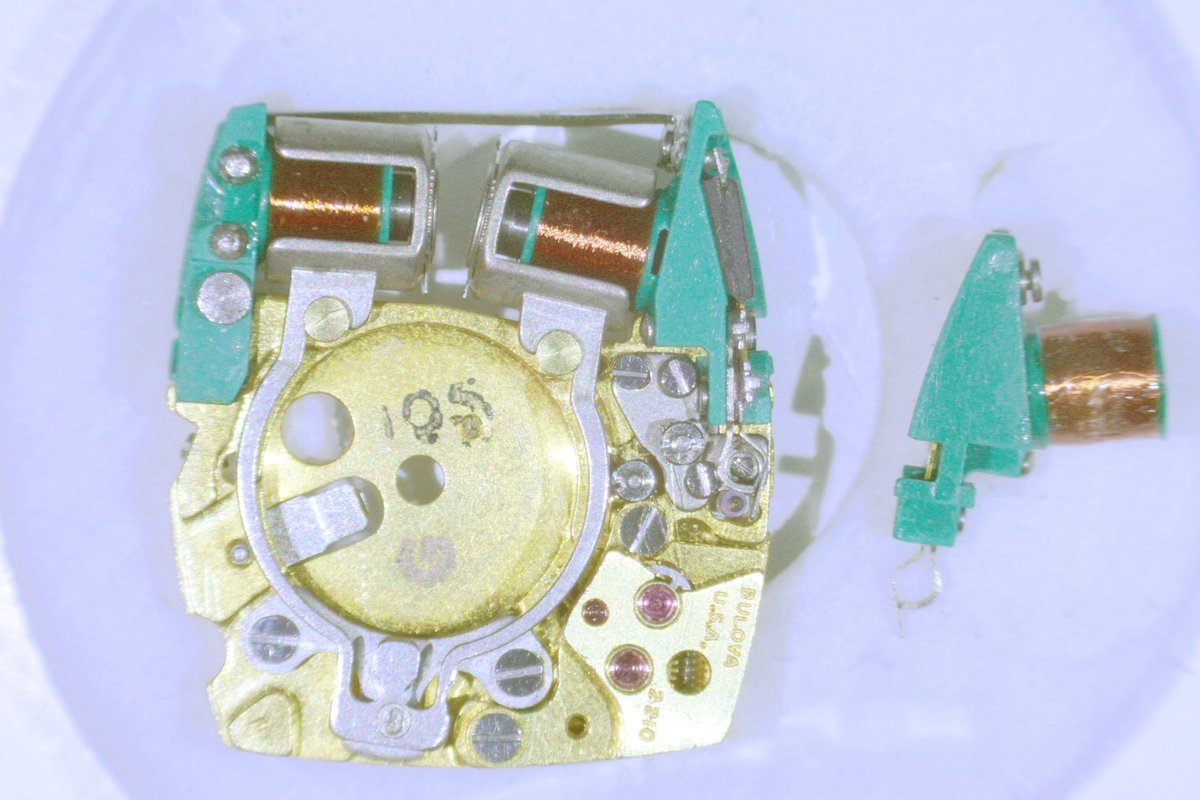

The Accutron 2210 is one of the smallest tuning fork movements ever produced. I acquired the movement below from an ebay auction together with futher tuning fork movement replacement parts.

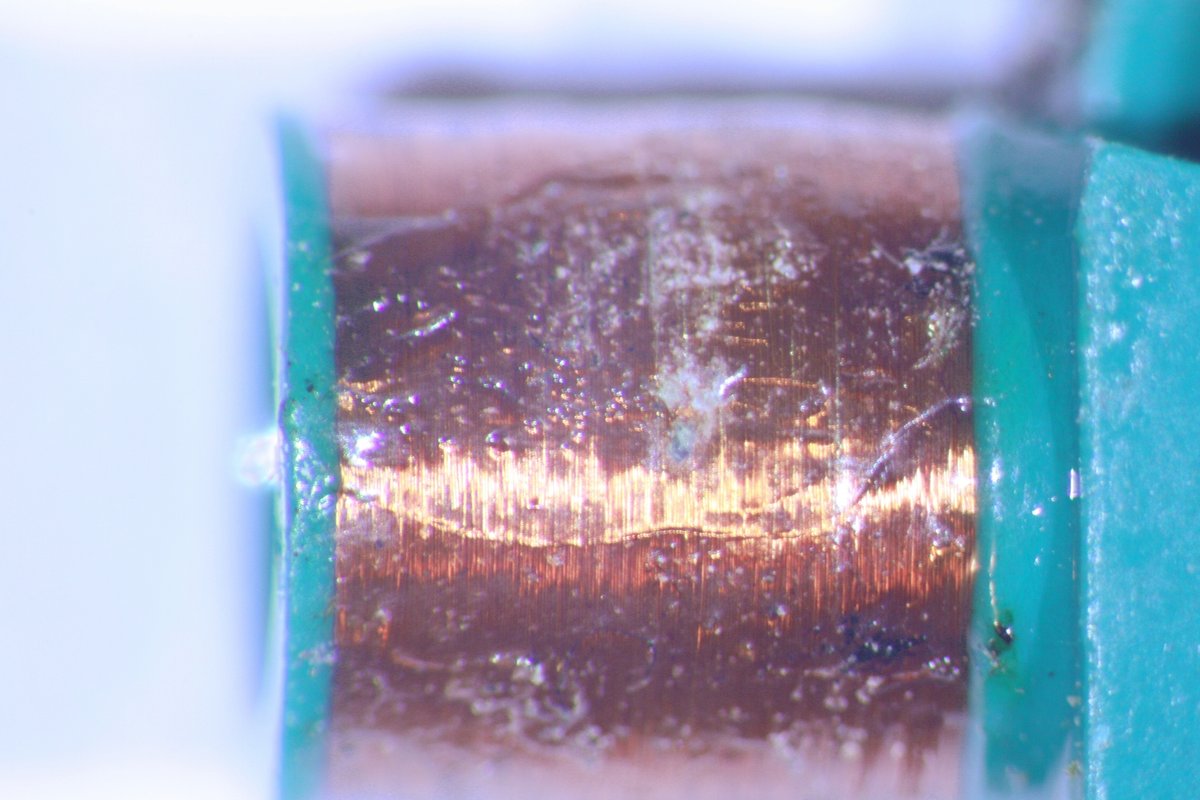

Sadly, it was not working although its two coils (A + B) not only seemed visually intact but also had the right resistance values. It was the IC which actually seemed to be faulty if I compared its values with that of another drive coil from the auction (C). As the coil of the latter was broken beyond any repair - see the picture below which I took under my microscope - I decided to try to desolder the presumably working IC from the dead coil and combine it with the intact one.

De- and Re-soldering the Accutron IC

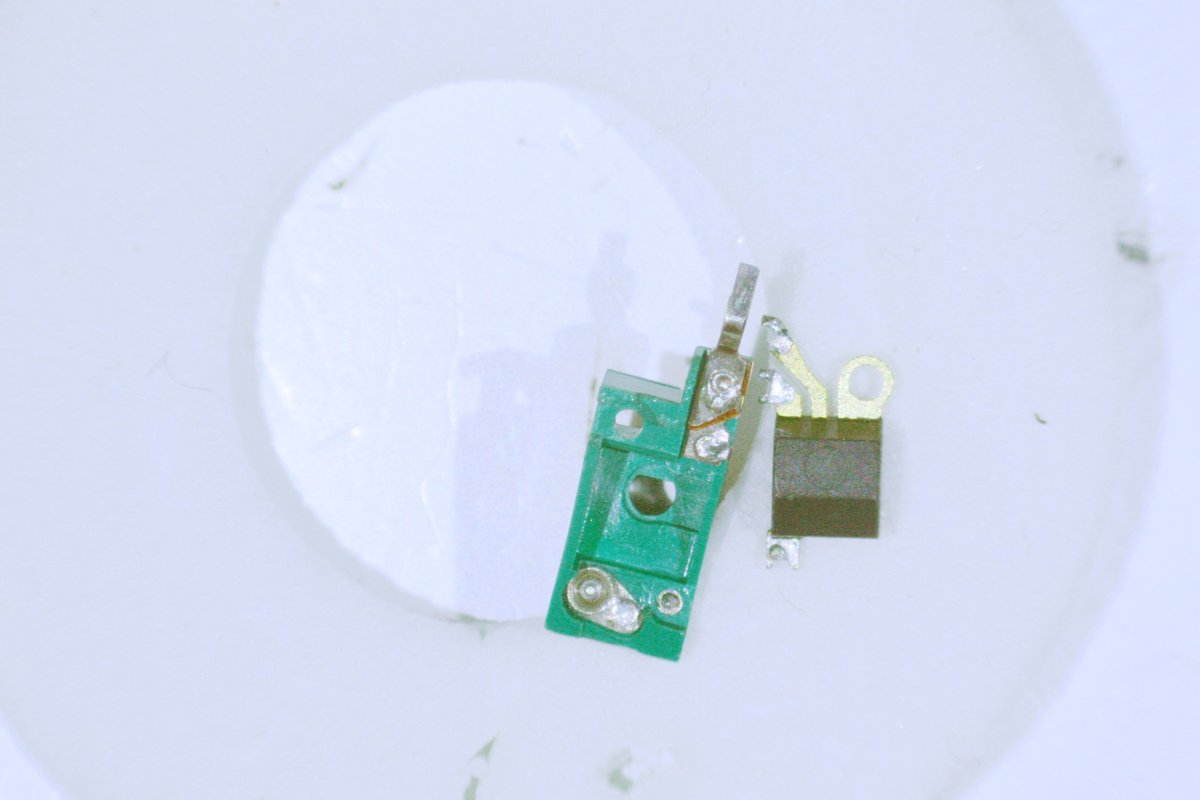

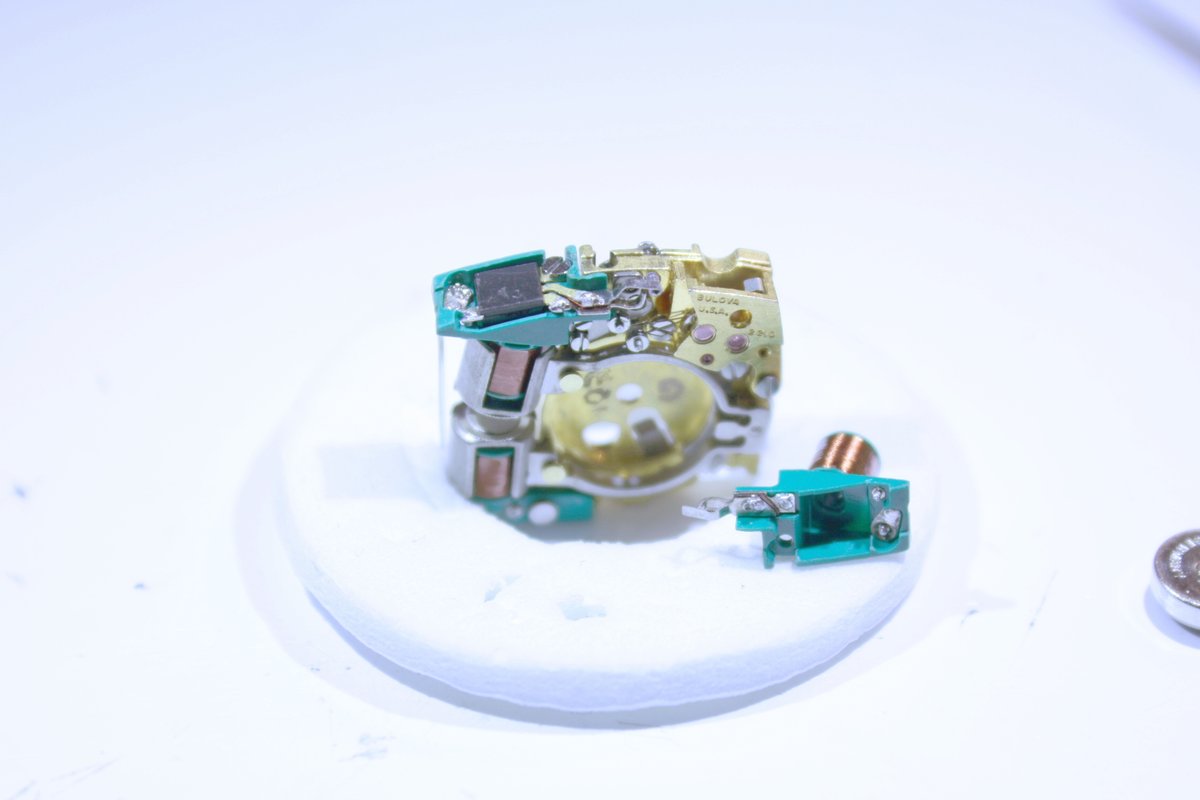

Four solder joints needed to be opened to get the IC out of its mounting - I used a SMD soldering station under the microscope to achieve this.

Soldering it to the other coil was much easier. To allow for a faster soldering speed - I did not want do damage the fine coil wire / plastic by excessive heat - I used some solder flux which I applied with a needle tip.

With the replaced IC the tuning fork movement started humming again when I powered it up - maybe I will post videos of the tuning fork movement in action in a future blog entry.

greetings noq2

Comments